Environmental Engineering Reference

In-Depth Information

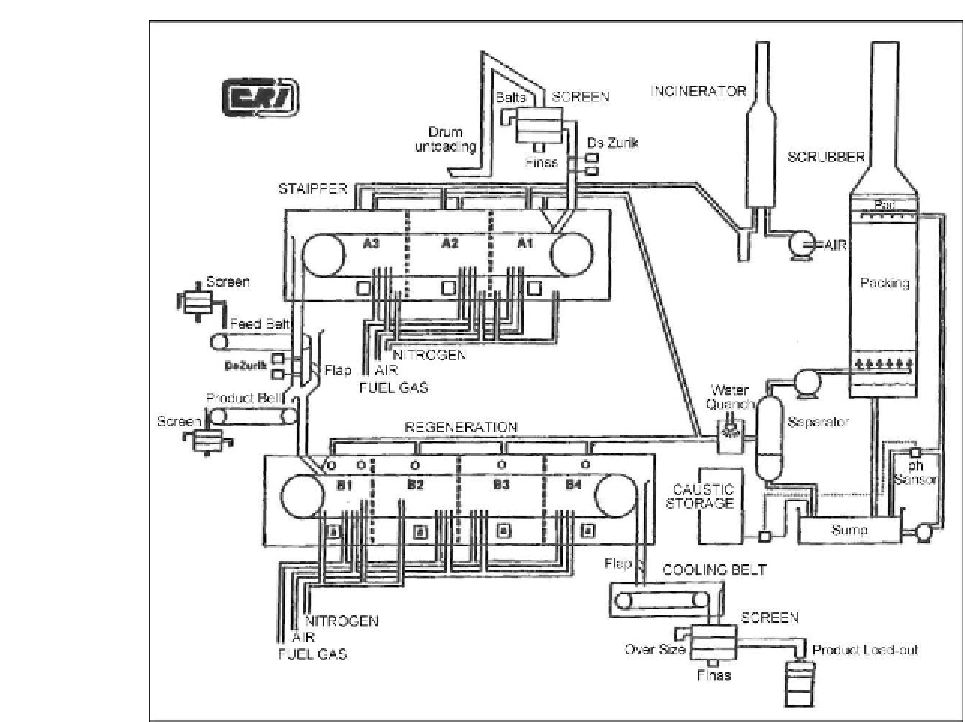

Figure 6.38: Schematics of CRI-MET regeneration process [From ref.

467

. Reprinted with

permission].

using four separate burners. This provides a flexibility required for temperature control.

Catalyst bed temperature is continuously monitored at 30 different points. The thickness of

catalyst bed, the speed of conveyor, air supply, and fuel input into the burners are all important

parameters for maintaining a precise temperature control. If necessary, the nitrogen system is

available for additional temperature control.

The movement of catalyst through the stripping and regeneration zones is more clearly viewed

in the simplified flowsheet of the belt process shown in

Fig. 6.40 [468,469]

.

Figure 6.40

also

shows the integration of the moving-belt process with the fluidized bed pretreater, i.e.,

OptiCat-Plus reactor. This integration resulted in the enhancement in the overall efficiency of

regeneration. The process consists of the fluidized bed reactor that strips hydrocarbons using