Environmental Engineering Reference

In-Depth Information

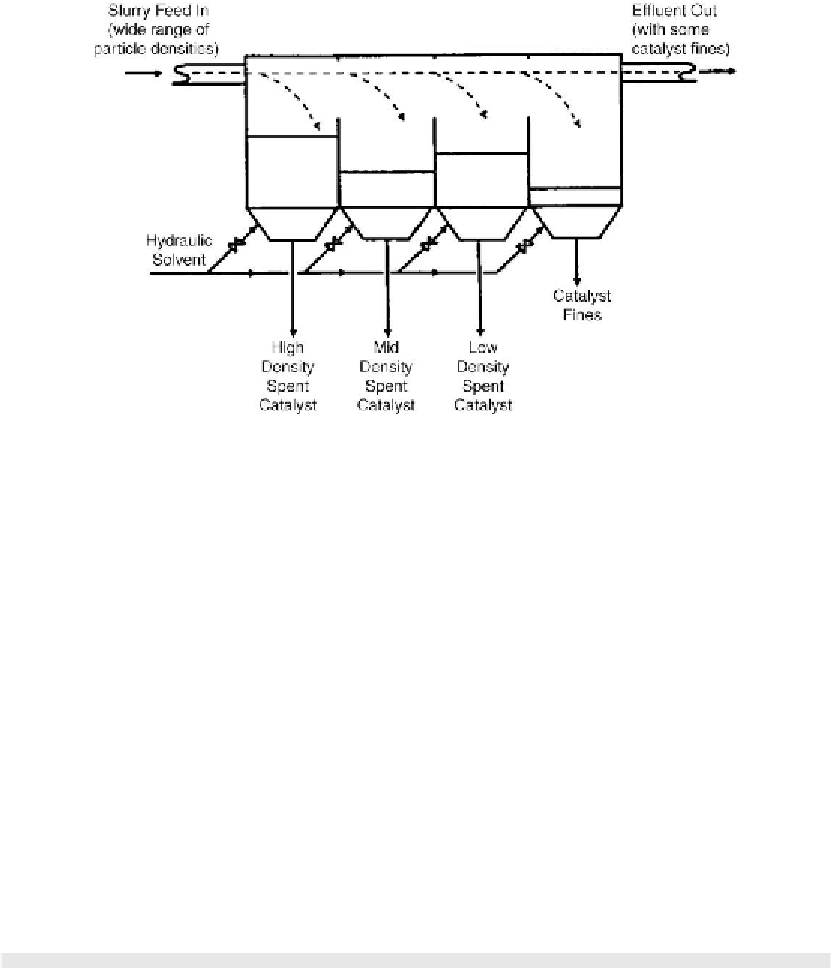

Figure 6.36: Schematic of gravity settling unit for catalyst separation [From ref.

462

. Reprinted

with permission].

applied to hydroprocessing catalysts of varying shapes and size particles as well as to the FCC

catalysts

[464]

.

The effectiveness of density grading is enhanced if the particles are of a uniform size. For

extrudate shape of particles, the length grading may be necessary prior to density grading. The

length-density grading according to vanadium content has been successfully applied

[465]

.

This was based on the observations that the compacted bulk density and surface area of spent

catalyst correlated with the level of vanadium contamination. The results of length grading of

the spent NiMo/Al

2

O

3

catalyst are shown in

Table 6.11

, whereas the particle distribution of

spent catalyst as received and the fraction of 1.5-3.5mm in

Fig. 6.37 [465]

. The 1.5-3.5mm

fraction accounted for more than 70 wt.% of the spent catalyst. The fraction of particles shorter

than 1.5mm had to be rejected before regeneration. The remaining spent catalyst was

subjected to density grading to obtain four fractions, i.e., light, medium-light, medium-heavy,

Table 6.11: Yield and average length of particles after length grading [From ref.

465

. Reprinted

with permission].

Catalyst

Yield (wt.%)

Average length (mm)

Fresh

0

2

.

3

<

1.5 mm

16

1

,

2

1.5-3.5

71

2

.

3

>

3.5

13

3

.

6