Environmental Engineering Reference

In-Depth Information

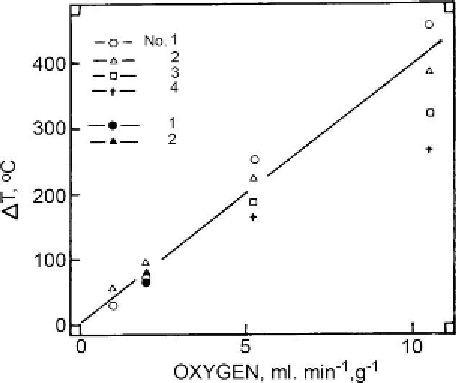

Figure 6.26: Effect of O

2

concentration in regeneration gas on temperature runway in four zones

of fixed bed (solid symbols for tetrahydrofuran [THF] extracted catalyst) [From refs

419

and

420

. Reprinted with permission].

of spent catalyst was 350

◦

C. From this correlation, it can be estimated that the O

2

concentration of about 4 vol.% can ensure the temperature excursion to less than 500

◦

C. Thus,

according to

Figs 6.17 and 6.22 [401,367,368]

, in order to achieve a high recovery of catalyst

activity, the temperature of regeneration should not exceed 500

◦

C.

The correlation in

Fig. 6.26 [420]

is applicable to a specific spent catalyst, i.e., it cannot be

applied generally. This is confirmed by the results in

Fig. 6.25 [419]

. The temperature profiles

in

Figs 6.25 and 6.27

were obtained for catalyst A and catalyst B, respectively. The properties

of these catalysts are given in

Table 6.9

. The temperature excursion in air for the much more

coke deposited catalyst B was lower compared with that for catalyst A. This can be attributed

to a much smaller surface area of catalyst B, which allowed only an external chemically

Table 6.9: Composition of coke (wt.%) on spent catalysts [From ref.

419

. Reprinted with

permission].

Catalyst A

Catalyst B

Carbon

7

.

2

26

.

2

Hydrogen

0

.

8

3

.

5

H/C

1

.

3

1

.

6

Nitrogen

0

.

40

0

.

27

Sulfur

7

.

13

5

.

48