Environmental Engineering Reference

In-Depth Information

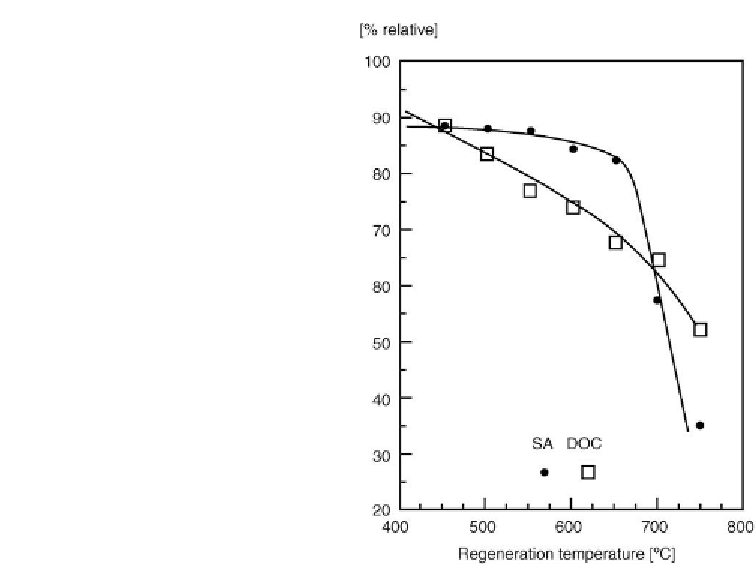

Figure 6.22: Effect of regeneration temperature on recovery of surface area (SA) and on dynamic

O

2

chemisorption (DOC) [From refs

367

and

368

. Reprinted with permission].

The usefulness of the O

2

chemisorption method was also confirmed by Cable et al.

[406]

.In

agreement with

Fig. 6.18 [401]

, the abrupt surface area decline above 600

◦

C was rather

evident. At the same time, the decline in the DOC was more gradual. Nevertheless, only

regeneration below 500

◦

C ensured a desirable level of the activity recovery. The DOC values

were consistently lower than corresponding surface area values suggesting that a high recovery

of surface area does not ensure a high recovery of activity. However, these observations cannot

be generalized. For example, Inoguchi et al.

[407]

reported that a complete recovery of both

surface area and activity was achieved for a spent catalyst deactivated only by coke, whereas in

the presence of contaminant metals neither surface area nor activity of the fresh catalyst could

be restored on regeneration. Another set of interesting data was published by Sakabe and Yagi

[408]

who studied regeneration of the spent CoMo/Al

2

O

3

catalyst used for hydroprocessing of

a residue. For this catalyst, a loss in the HDS activity on regeneration was observed. At the

same time, the activity of the catalyst for hydrocracking reactions improved. Similar

observation was made by Cable et al.

[406]

. Then, the regenerated catalyst may be used in an

operation requiring a high hydrocracking service, although this observation cannot be

generalized.