Environmental Engineering Reference

In-Depth Information

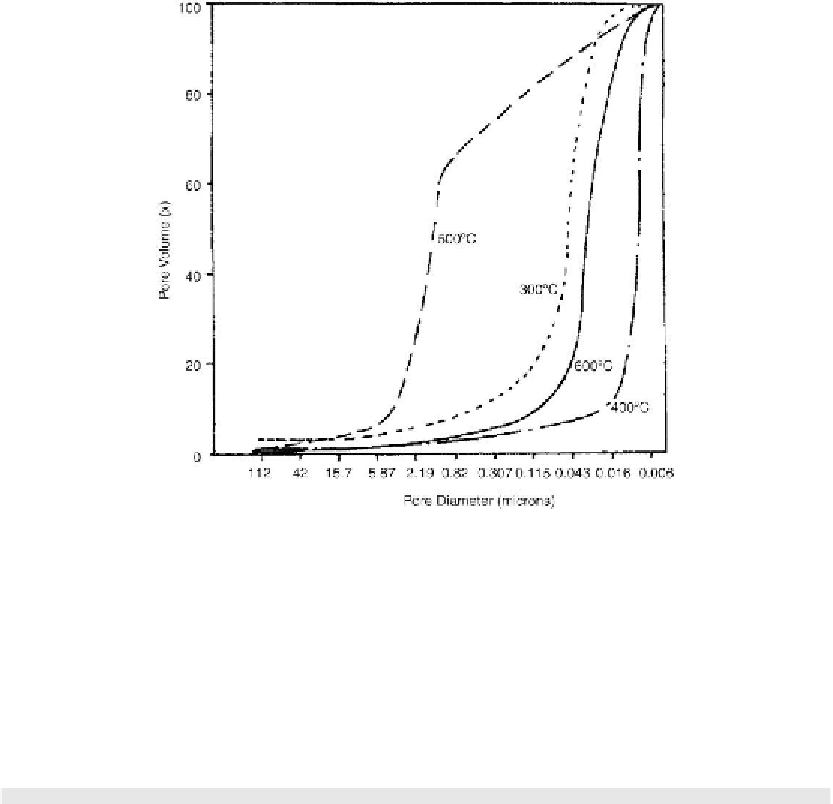

Figure 6.19: Effect of regeneration temperature on pore size distribution of catalyst [From ref.

401

. Reprinted with permission].

surface area recovery for the NiMo/Al

2

O

3

catalyst in 2% O

2

was quite surprising because this

catalyst was deactivated by metals in addition to coke. A visual observation of the particles

after regeneration in air indicated the presence of glassy phases, thus confirming a significant

sintering.

Table 6.5: Surface area (m

2

/g) loss and recovery on fresh catalyst surface area [From ref.

331

.

Reprinted with permission].

CoMo/Al

2

O

3

NiMo/Al

2

O

3

Fresh

210

140

Spent

167

17

Treated in N

2

182

50

Surface area loss (%)

11

64

Regenerated

In air

90

54

In 2% O

2

197

127

Surface area recovery (%)

In air

43

39

In 2% O

2

94

91