Environmental Engineering Reference

In-Depth Information

underestimate of the rate constants. This was particularly evident for the catalyst that was not

presulfided prior to hydroprocessing test. As it was indicated earlier, reliable values of the

kinetic parameters can only be obtained from the determination of products with time on

stream. These values are much higher than those from the TGA tests. This may be attributed to

the turbulent flow present in the fixed bed reactor compared with the laminar flow present in

the TGA system. The former ensured more efficient contact of O

2

with spent catalyst. Also,

the rate constants for sulfided catalyst were consistently higher than those for the oxidic

catalyst. Most likely, this was caused by the difference in reactivity of coke. Thus, because of a

higher hydrogenation activity, the coke on sulfided catalyst should be less refractory, i.e.,

softer, compared with the coke on the oxidic catalyst. This was supported by the higher H/C

ratio of coke on the former spent catalyst.

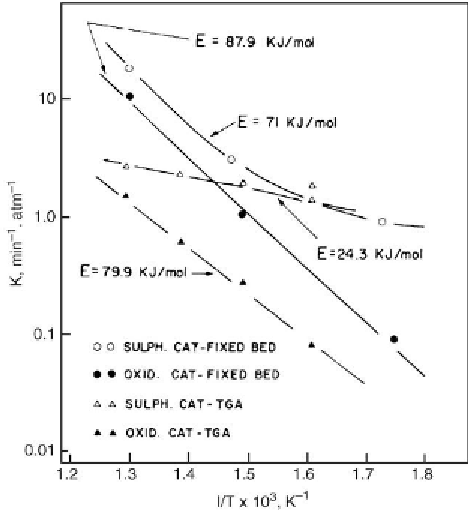

The rate constants in

Table 6.3 [387]

were expressed in the form of Arrhenius plots (

Fig. 6.14

)

[391]

for the estimate of activation energies. It should be noted that these rate constants were

determined during very early stages of burn-off, i.e., during less than 50 s. Therefore, they

represent chemically controlled burn unaffected by diffusion. Activation energies for the

oxidic catalyst were consistently higher than those for the sulfided catalyst. For the latter

catalyst, the activation energy obtained from TGA results was affected by the weight loss

Figure 6.14: Log k versus 1/

T

correlations for burn-off performed in fixed bed and TGA reactors

[From ref.

391

. Reprinted with permission].