Environmental Engineering Reference

In-Depth Information

formation during the exposure of sulfided catalysts to air cannot be ruled out. The sulfate

formation during the exposure to air was also postulated in

Chapter 5

for spent catalysts.

A significant complexity of the mechanism of the oxidative regeneration of spent catalysts

should be noted. This results from rather complex nature of coke and metals, which deposit on

catalyst surface during the operation. Thus, only recently, the chemical structure of such coke

was described in more details

[238,239]

. The interaction of coke with catalyst surface during

regeneration is an important part of the overall mechanism. Because of the structural

complexity and continuous change, the involvement of the inorganic part of spent catalysts

during regeneration needs to be further investigated. Therefore, some assumptions and/or even

speculation while discussing the mechanistic aspects of the oxidative regeneration of spent

hydroprocessing catalysts could not be avoided.

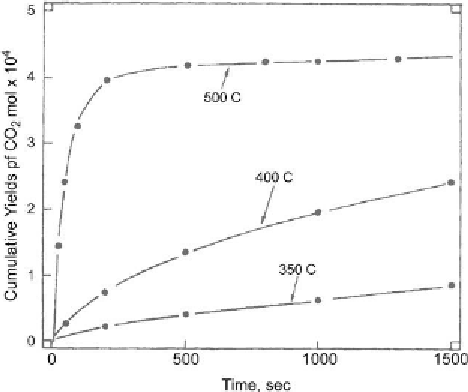

6.2.2 Kinetics of Oxidative Regeneration

The estimate of kinetic parameters may be desirable to obtain a more quantitative picture of

regeneration process. There are several methods that can be used for quantifying the removal

of coke during regeneration. The method based on the change in conversion with time on

stream requires several burn-off experiments performed under the same conditions but at

different duration. Apparently, the most suitable method involves the quantitative on-line

analysis of all burn-off products in the course of the experiments. An example of such results

is shown in

Fig. 6.11 [374]

correlating cumulative yields of CO

2

with time at different

Figure 6.11: Cumulative yields of CO

2

from isothermal burn off of spent catalyst in air [From

ref.

374

. Reprinted with permission].