Environmental Engineering Reference

In-Depth Information

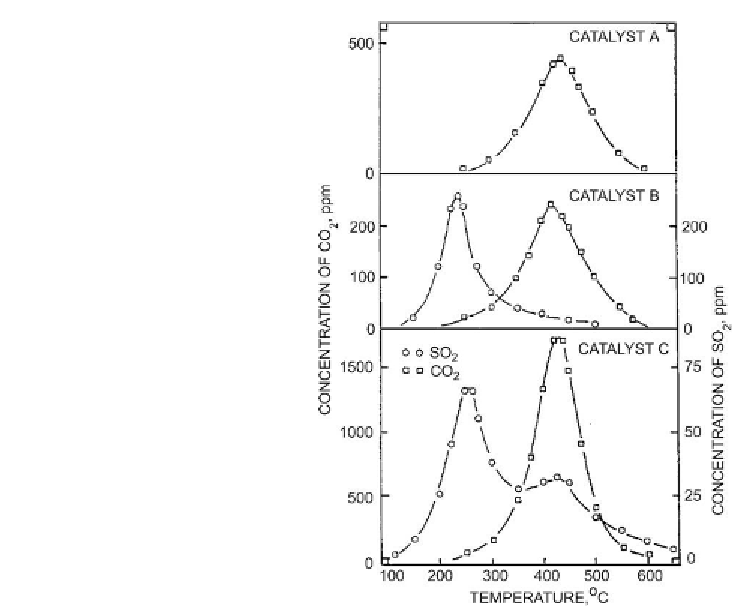

Figure 6.5: Formation of SO

2

and CO

2

during temperature programmed oxidation (TPO) of

spent catalyst [From ref.

369

. Reprinted with permission].

temperature region coincides with the formation of CO

2

and can be almost certainly attributed

to the oxidation of organic sulfur in coke. The catalysts in

Fig. 6.5 [369]

were crushed to

100-200mesh before TPO experiments to minimize the interference of diffusion. The trends

observed in

Fig. 6.5

are in agreement with the studies published by Zeuthen et al.

[370,371]

.

Matsushita et al.

[240]

evaluated the spent catalysts from the study of Hauser et al.

[238,239]

using the TPO technique. The spent catalysts were used for hydroprocessing the atmospheric

residue derived from a Kuwait crude. They were taken at different stages on stream during the

same operation. The TPO profiles (

Fig. 6.6

) revealed the two maxima of CO

2

formation, i.e.,

one at about 573 K and the other at about 700 K. These maxima were attributed to the

oxidation of a “soft” coke and a “hard” coke, respectively. It should be noted that in the study

of Seki and Yoshimoto

[208]

, the “hard” coke was defined as toluene insoluble portion of

coke. The “hard” coke studied by Hauser et al.

[239]

was much more refractory and was

adsorbed strongly on the catalyst surface. In its structure, the “soft” coke in the Hauser et al.

[238]

study may approach the structure of the toluene insolubles portion of coke formed