Environmental Engineering Reference

In-Depth Information

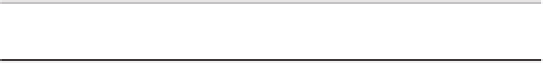

Ta b l e 6 . 4

Parameters of evolution of metal-containing molecules in hot argon (

p

D

1atm,

c

M

D

10%,

0

D

1mm).

Compound

MoF

6

IrF

6

WF

6

WCl

6

,g/cm

3

2.6

6.0

3.4

3.5

T

m

, K

290

317

276

548

T

b

, K

310

326

291

620

ε

X

, eV

4.3

2.5

4.9

3.6

ε

M

, eV

6.3

6.5

8.4

8.4

T

1

, K

2200

1200

2500

1700

T

2

, K

4100

4000

5200

5200

T

,10

3

K

δ

12

3.7

13

4.8

T

, K

3600

2900

4600

4200

N

m

,10

16

cm

3

2.0

2.5

1.6

1.8

dM

/

dt

,

μ

g/s

0.66

1.2

0.74

1.1

dl

/

dt

, nm/s

23

20

13

20

τ

chem

,10

3

s

5

0.1

1

0.1

τ

heat

,10

4

s

2.0

2.8

1.3

1.5

10

7

10

7

10

7

10

7

n

1.6

1.9

1.5

1.5

r

, nm

40

42

40

40

N

cl

,10

9

cm

3

1.2

1.3

1.1

1.1

D

0

,cm

2

/s

25

18

36

31

q

2

,

μ

m

88

71

110

100

to the transport process is not strong. Released metal atoms join in clusters, and for

the basic time of residence of this mixture in the tube

0.1 s the cluster growth

pr

ocess proceeds through coagulation. We give in Table 6.4 the average cluster size

n

according to (6.82) at the end of the coagulation process together with its radius

r

,

and the number density of clusters

N

cl

.

Let us evaluate the broadening of the region occupied by metal clusters as a

result of diffusion in the course of the cluster growth process. We have for the

mean square displacement during this process

τ

D

dr

4

Z

Ddt

4

D

0

Z

dt

n

2/3

D

20

D

0

τ

dr

2

D

D

.

(6.94)

n

2/3

We used above the case of cluster diffusion in a rare gas (4.110) and (4.114) for the

diffusion coefficient. As is seen, the relative displacement of clusters in the course

of their growth is small.