Image Processing Reference

In-Depth Information

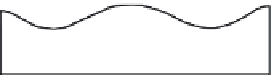

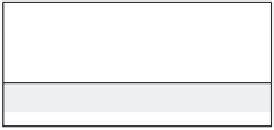

OCL

Separation

wall

Color filter

Light pipe

Copper wiring

layers

Photodiode

Si substrate

FIGURE 5.71

Cross-sectional view of advanced FSI. (Reprinted with permission from Watanabe, H., Hirai, J., Katsuno, M.,

Tachikawa, K., Tsuji, S., Kataoka, M., Kawagishi, S. et al.,

Proceedings of the IEEE International Electron Devices

Meeting, Technical Digest

, 8.3, pp. 179-182, Washington, DC, 2011.)

Stack technology might compensate for the disadvantageous cost-effectiveness of BSI and

may achieve high-speed processing.

5.3.3.3.3 Front Side Illuminated Sensor

In a recent advanced front side illuminated sensor (SmartFSI

®

*), it was shown

59

that FSIs

achieve performance comparable to that of BSIs. A cross-sectional view with an actual

aspect is shown in Figure 5.71.

The pixel pitch is 1.4 μm. The essential point is how effectively incident rays pass through

wiring layers and propagate toward the PD and are captured. To this end, the following

techniques are adopted: (1) Lightpipe capability is added to the color filter by forming a

low refractive index separation wall between each pixel color filter. Therefore, incident

light propagates downward. (2) The aperture area is enlarged and the optical stack height

is lowered. This is achieved by shrinking the thickness and width of low-resistance copper

layers. (3) The original lightpipe is made shallow and powered up due to the high refrac-

tive index SiN used on the lightpipe core. (4) A deep PD is formed to effectively capture

longer-wavelength light guided to the PD. By using these techniques, quantum efficiency

(QE) by simulation of green light (wavelength 520 nm) is 73.9%, while those of conven-

tional FSIs with a deep lightpipe and BSIs with a light shield film are 42.9% and 69.3%,

respectively.

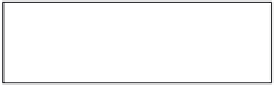

Figure 5.72 shows the light energy attenuation along the light propagation direction from

the top of the OCL on the extreme right to the silicon surface on the far left. The coordinate

value of the abscissa axis shows the height from the silicon surface. The arrows indicate

the energy loss through a green filter. The reason they do not start from 100% is that light

reflected at the silicon surface and returned to the OCL is subtracted just above the OCL in

the simulation. The energy loss through the color filter for the SmartFSI is 3%, while that

for the BSI is 14%. The light confinement effect of the separation walls to the color filter

prevents energy attenuation at the color filter boundary. The light waves are effectively

guided and confined through the color filter between the separation walls and through the

lightpipe between the metal apertures and focused on the PD. Peak quantum efficiencies

*

SmartFSI is a trademark of Panasonic Corporation.