Image Processing Reference

In-Depth Information

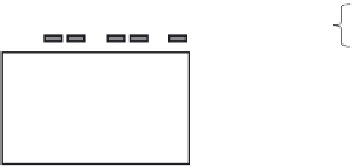

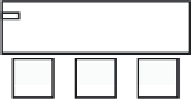

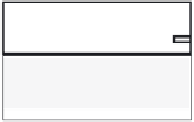

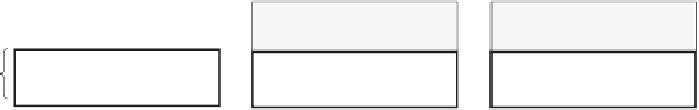

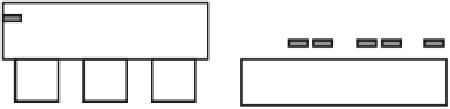

Metal

wiring

layers

Silicon layer

thickness:

∼3 μm

PD

PD

PD

Metal

wiring

layers

PD

PD

PD

Silicon

substrate

thickness:

600-800 μm

Supporting substrate

(a)

(b)

FIGURE 5.67

Schematic diagram of a simplified cross-sectional view of (a) a surface illustrated sensor (FSI); (b) a backside

illuminated sensor (BSI).

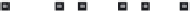

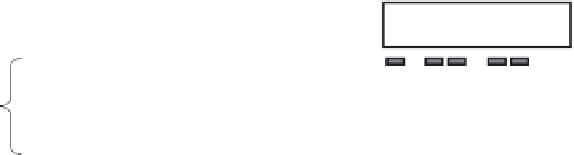

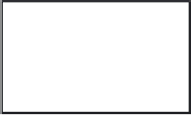

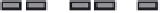

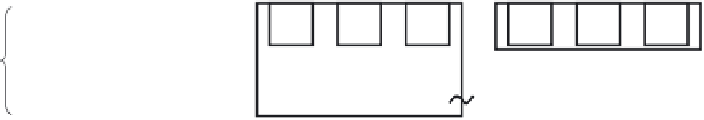

Support substrate

Support substrate

Metal

wiring

layers

PD

PD

PD

PD

PD

PD

PD

PD

PD

Silicon

substrate

ickness: ∼3 μm

(a)

(b)

(c)

OCL

p

+

layer

Light shield film

Color filter

PD

PD

PD

PD

PD

PD

Support substrate

Support substrate

(d)

(e)

FIGURE 5.68

Conceptual diagram of the fabrication process of a BSI: (a) formation of circuitry and wiring on a silicon wafer;

(b) attachment of support substrate; (c) wafer thinning; (d) backside passivation and light shield formation;

(e) color filter and OCL formation.

shown in Figure 5.68b-d were newly added for BSIs. Image sensors are a kind of LSI and

have been naturally manufactured by technology cultivated in the LSI industry including

the fabrication process. Technologies inherent in image sensors hitherto include intrinsic

gettering (IG),

56

IG-epi wafers,

57

buried/pinned PDs, color filters, OCLs, glass-sealed pack-

ages, and so on. BSIs have a greatly expanded technological area endemic to image sensors

quantitatively and qualitatively. While newly added processes increase the manufacturing

cost, they should bring about benefits that outweigh this cost increase for the industry.

Figures 5.67 and 5.68 show conceptual drawings. High optical performances, such as

sensitivity, are expected of BSIs, especially in smaller size pixels.