Image Processing Reference

In-Depth Information

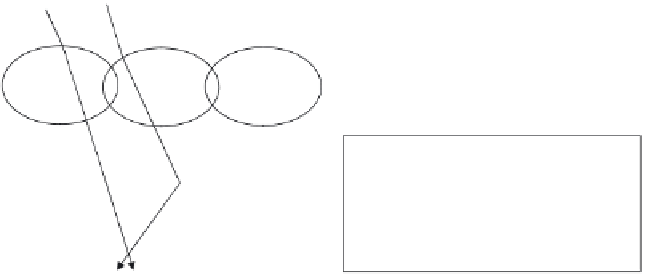

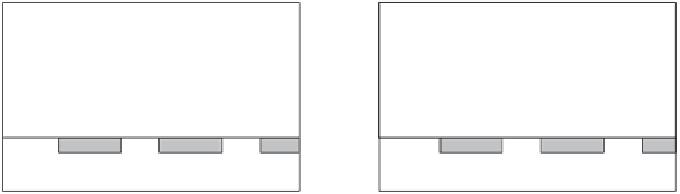

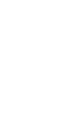

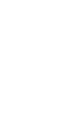

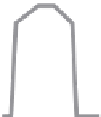

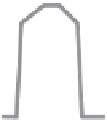

OCL

Color

filter

M

4

M

3

M

2

M

1

Photodiode

Photodiode

Si

Si

Lightguide

(filled with high refractive index material)

(a)

(b)

FIGURE 5.66

Schematic diagram of a CMOS sensor with a four-metal-layer wiring pixel: (a) without a lightguide; (b) with a

lightguide. (Reprinted with permission from Gambino, J., Leidy, B., Adkisson, J., Jaffe, M., Rassel, R.J., Wynne, J.,

Ellis-Monaghan, J. et al.,

Proceedings of the International Electron Devices Meeting

,

Technical Digest

, pp. 5.5.1-5.5.4,

San Francisco, CA, 2006.)

material,

52

as shown in Figure 5.66b. While OCLs correspond to sharpshooting, as it

were, in lightpipe sensors incident light is confined in high refractive index material and

guided to the PD, similar to a funnel. Using this method, loss of light and cross talk can

be suppressed.

5.3.3.3.2 Backside Illuminated Sensors

Backside illuminated sensors (BSIs) have a structure in which incident light can directly

reach the PD without passing through metal layers by receiving light from the backside

or the substrate side of sensors. Although BSIs were proposed with the first FT-CCD

4

in

1972, processing to fabricate thin silicon wafers is complicated and expensive. This was

adopted only for special applications such as scientific measurements

53

and was used only

for monochrome image sensors. When a BSI-type CMOS sensor

54

was proposed for a con-

sumer SCCC, a big trend

55

was started. Schematic diagrams of cross-sectional views of a

front-side illuminated sensor (FSI) and a BSI are compared in Figure 5.67.

While incident light has to pass through metal wiring layers in the FSI, light can arrive

at the PD directly in the BSI. Therefore, the BSI has some advantage in sensitivity over the

FSI. This is very easy to understand through instinct, that is, advantageous technology

for monochrome sensors. For this reason, not only people who are unfamiliar with image

sensor technology but also those who should be experts on it often misunderstand that the

BSI has an absolute advantage in sensitivity over the FSI without any conditions. This will

be described in detail in this section and Section 5.3.3.3.3.

From the viewpoint of pixel design, flexibility of metal layout is of great benefit in BSIs.

The process flow shown in Figure 5.68 is necessary to implement a BSI structure. (a) At

the first PD, a circuit and wiring are formed, as well as an FSI. (b) Then, a supporting sub-

strate is attached to the surface side. (c) Wafer thinning is followed by grinding and etch-

ing. (d) New backside surface is processed to suppress dark current and a light shield film

is formed. (e) Formation of color filters and OCLs completes the process flow. The steps