Environmental Engineering Reference

In-Depth Information

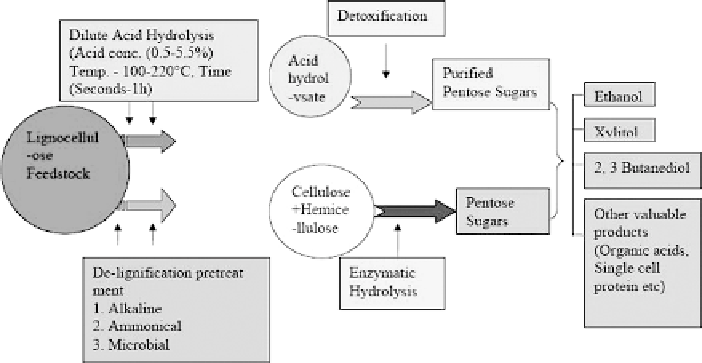

Fig. 1

Mechanistic steps involved in hemicellulose bioconversion into ethanol, xylitol and

2, 3-butanediol

industry. However, several yeast species have the basic ability to carry out these

processes, i.e.,

Candida shehatae, Pichia stipitis,

and

Pachysolen tannophilus

for

ethanol production;

C. utilis

,

C. intermedia

, and

C. gulliermondii

for xylitol pro-

duction; and

Klebsiella oxytoca

ATCC 8724,

Bacillus subtilis

(Ford strain), and

Aeromonas hydrophilia

for 2, 3-butanediol production [4]. This chapter presents sig-

nificant advancements in hemicellulose biotechnology, with an emphasis on acidic

and enzymatic hydrolysis and the conversion of hemicellulose hydrolysates into

commercial products like ethanol, xylitol, and 2, 3-BD.

2 Background Research

To reduce the production of greenhouse gases and ensure sustainable global eco-

nomic development, it is important to increase the use of renewable biomass

resources [14]. There have been active movements accelerating the utilization of

lignocellulose-derived products such as bioethanol, xylitol, microbial enzymes, and

2, 3-BD into alternative source of bioenergy [4, 15, 16]. Ethanol has drawn the most

attention due to its rapid consumption and the global price fluctuations of crude

petroleum [15, 17].

Due to developments in industrial biotechnology, the carbohydrate fraction of the

cell wall can be converted into products of industrial significance. However, hemi-

cellulose has been explored less extensively than cellulose due to several factors.

The hemicelluloses in lignocellulosic materials are broken down into fermentable

sugars by either chemical or enzymatic hydrolysis [18]. The latter is a promising

method that breaks down hemicellulosic materials into fermentable sugars without

Search WWH ::

Custom Search