Environmental Engineering Reference

In-Depth Information

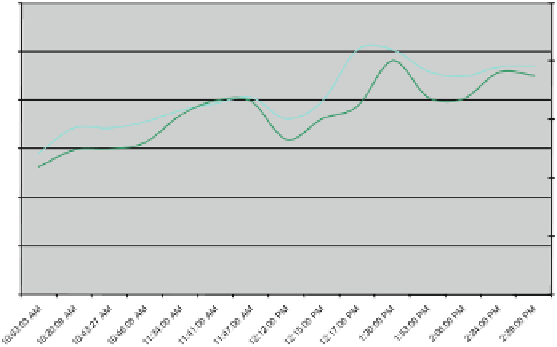

Fuel Efficiency - 1 AUG 08

Off Board Power

Diesel Flow (GPH)

60

2.5

50

2

40

1.5

30

1

20

0.5

10

0

0

Fig. 12

Fuel efficiency and power (1 August 08)

Table 4 shows the use of the TGER Energy Conversion Model to analyze the per-

formance of the TGER on 1 August 08. Biofuels contributed 92.92% of the required

energy to generate electricity and diesel fuel contributed 7.08%. This shows that the

TGER can run almost entirely on biofuels, although the increase in biofuel contribu-

tion did have a negative affect on the thermal to electrical conversion efficiency. The

increase in the contribution of energy from biofuels lowered the thermal to electrical

conversion efficiency from 23% on 30 May 08 to 16.8% on 1 August 08, which is

attributable to the fact that the Kohler generator was specifically designed to run on

diesel, rather than biofuels.

5 Expert Commentary and Five Year View

The Tactical Garbage to Energy Refinery (TGER) is a trailerable, skid-mounted

device capable of converting waste products (paper, plastic, packaging and food

waste) into electricity via a standard 60 kW diesel generator. Additionally, the sys-

tem can utilize available local biomass as a feedstock. Waste materials are converted

into bio-energetics which displaces the diesel fuel used to power the generator set.

The system also co-produces excess thermal energy which can be further utilized

via a “plug and play” heat exchanger to drive field sanitation, shower, laundry or

cooling devices. With additional engineering, the TGER could include a small sub-

system to recover water introduced with the wet waste and produce potable water

to further reduce logistics overhead. The system requires a small “laundry packet”

of enzymes, yeasts and industrial antibiotics to support the biocatalytic subsystem.

Search WWH ::

Custom Search