Environmental Engineering Reference

In-Depth Information

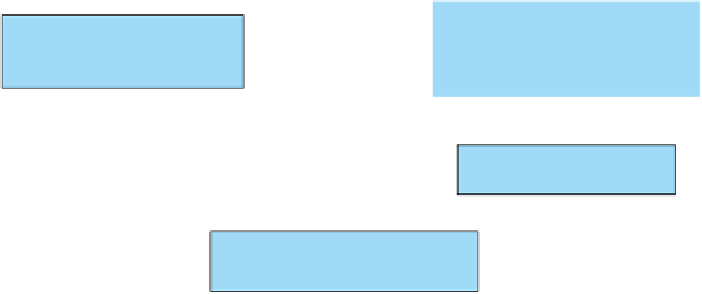

• shape and size of material

• vegetation

• surface irregularities

(construction, maintenance type)

• shape and size of material

• surface irregularities

(bed forms)

roughness in the bed

roughness in the sides

• shape of canal

• bed width to water depth ratio

equivalent roughness

Figure 5.3.

Process to derive the equivalent roughness.

the development of bed forms on the bottom, different roughness along

the bottom and the sides, and vegetation on the side banks. Canals with

different roughness along the perimeter need an equivalent roughness that

should be based on the weighted roughness of the various components. In

the past, several methods have been developed to compute the equivalent

roughness from some basic assumptions concerning the flow in the canal.

5.2.2

Bed form development

In alluvial canals there exist two flow stages, one without any movement

of bed material and the other with movement of the bed material. Canals

without movement of bed material can be compared with a rigid boundary

canal having an equivalent roughness height (

k

s

) equal to the representative

bed material size (

d

). The resistance to flow in a movable bed consisting

of sediment is mainly due to the grain roughness and form roughness. The

grain roughness is generated by a skin friction force and form roughness

due to forces acting on the bed forms.

Bed forms will continuously change with the flow parameters

(velocity, depth) and therefore the bed roughness will also change.

There are two approaches to estimate the bed roughness:

•

methods based on hydraulic parameters such as mean depth, mean

velocity and bed material size;

•

methods based on bed form and grain-related parameters such as bed

form length, height, steepness and bed-material size.

The methods based on the hydraulic parameters by Einstein and

Barbarossa (1952), Engelund (1966), White et al. (1980), and Brownlie

(1981b) are the most widely used ones. These methods do not explicitly

Search WWH ::

Custom Search