Environmental Engineering Reference

In-Depth Information

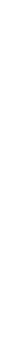

Profile of Waste Rock Formed by

Top Down Construction

Crest

Over-Steepened (unstable) Slope

Angle of Repose (meta-stable) Slope

37.38

°

Original Ground Surface

Rill Slope-

Larger Boulders

Waste Rock Dump by Top-down Dumping, Chhattisgarh, India

Profile of Waste Rock Formed by

Bottom Up Construction

Crest

13

12

11

Excavated

Drainage

Channel

10

9

8

Original Surface

7

6

5

4

To e

Paddock Dumping of Waste Rock. Three Layers are Visible - Lowest Layer at Left

FIGURE 19.4

Profi le of Waste Rock Storage

Formed by Top Down and Bottom Up

Construction

Marine disposal of waste rock was used at the Misima Gold Project in PNG, and is cur-

rently used at the Lihir Gold Project (also in PNG). In both cases, the reasons for adopt-

ing marine disposal were the lack of land suitable for onshore disposal and the predicted

low impacts of marine disposal. While both cases of marine disposal have been widely

criticized by environmental NGOs, monitoring has confirmed that impacts on the marine

environment have been relatively minor, temporary, and in accordance with predictions

made in the relevant EIAs.

While both cases of marine

disposal have been widely

criticized by environmental

NGOs, monitoring has

confi rmed that impacts on the

marine environment have been

relatively minor, temporary, and

in accordance with predictions

made in the relevant EIAs.

19.5 ALTERNATIVE DESIGN AND CONSTRUCTION

APPROACHES

There are two main approaches to construction of waste rock storages:

●

Top-down dumps, in which the waste rock is dumped over an advancing face, known as

the angle of repose, sloping at approximately 38º from the horizontal, as shown in profile

on the upper part of

Figure 19.4

. After dumping is complete, the dump is re-shaped to

its intended configuration, usually using bulldozers. In many older mining operations,

no re-shaping was carried out, the angle of repose slope being the final outslope.

●

Bottom-up storages in which the waste rock is dumped in a series of piles, and then spread to

form a relatively thin layer. This is sometimes referred to as paddock dumping (

Figure 19.4

).

Subsequently, the process is repeated until the ultimate storage configuration is achieved.

Hybrid or intermediate approaches are also used, whereby top-down dumping is used

to produce relatively thick, (e.g. 10 m or 15 m) layers, which are then overlain by subse-

quent equally thick layers. This approach is safer and requires less re-shaping than the full

height top-down approach.

The advantages and disadvantages of top down versus bottom up construction are com-

pared in

Table 19.1

.

Search WWH ::

Custom Search