Environmental Engineering Reference

In-Depth Information

Perimeter Sump

Perimeter sumps are used in the case of central discharge system storages and a few other

cases where relatively little water is available for recycling.

Operating Considerations

Operating requirements vary from case to case. However, the most common are:

●

Managing the discharge and decant systems so that the decant water is clear; i.e. it con-

tains no tailings solids.

●

Consistent with the above requirement, to minimize the pool area, thereby maximiz-

ing the area of exposed tailings beaches.

●

Achieving a relatively uniform accumulation of tailings around the perimeter of the

impoundment.

●

In some cases where the tailings embankments are not designed as water retention

structures, avoidance of the decant pool encroaching on any part of the embankment.

●

In other cases (e.g. the tailings/water storage for the Dizon Copper Project in Zambales,

Philippines), the tailings impoundment also serves as the major water storage for the

project. In such cases, water storage considerations take precedence over optimization of

tailings solids storage, the solids settle sub-aqueously and remain covered by water.

●

Commonly, l occulant is added to the tailings stream to assist in settling of i ne tailings

particles and to maintain a clear decant.

Segregation of Tailings

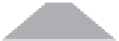

As previously mentioned, tailings particles discharged as slurry into conventional tailings

impoundments, will segregate as they deposit, due to the higher settling rates of larger

particles. As a result, coarser particles and any denser minerals will tend to deposit close to

the discharge point(s), with successively i ner particles depositing at increasing distances.

The i nest materials (slimes) will generally underlie the decant pond. A tailings deposit

with distinct segregation and permeability zones develops (Kealy and Bush 1971) (

Figure

18.14

). The slimes fraction of the tailings can be retrieved and applied to areas of an

impoundment that have high permeability zones that are causing seepage problems. The

blending will help to lower the permeability of the deposit.

Coarser particles and any denser

minerals will tend to deposit

close to the discharge point(s),

with successively fi ner particles

depositing at increasing distances.

FIGURE 18.14

Tailings Segregation Zones and Soil

Characteristics as a Function of

Distance from Spilling Location

ZONE 3

Low Permeability

Slimes

ZONE 2

Intermediate

Permeability

ZONE 1

High Permeability

Sand

The coarser fraction tends to settle

out closer to the tailings discharge

system and the slimes travel furthest

away generally towards the decant

pool. A tailings deposit with distinct

segregation and permeability zones

develops.

Source:

Based on Schoenhardt 2004 and ATV-DVWK-M503

2001

Decant Pool

Dam

Content of Fine Grain

Grain Size

Density

Permeability

Shear Strength

Search WWH ::

Custom Search