Environmental Engineering Reference

In-Depth Information

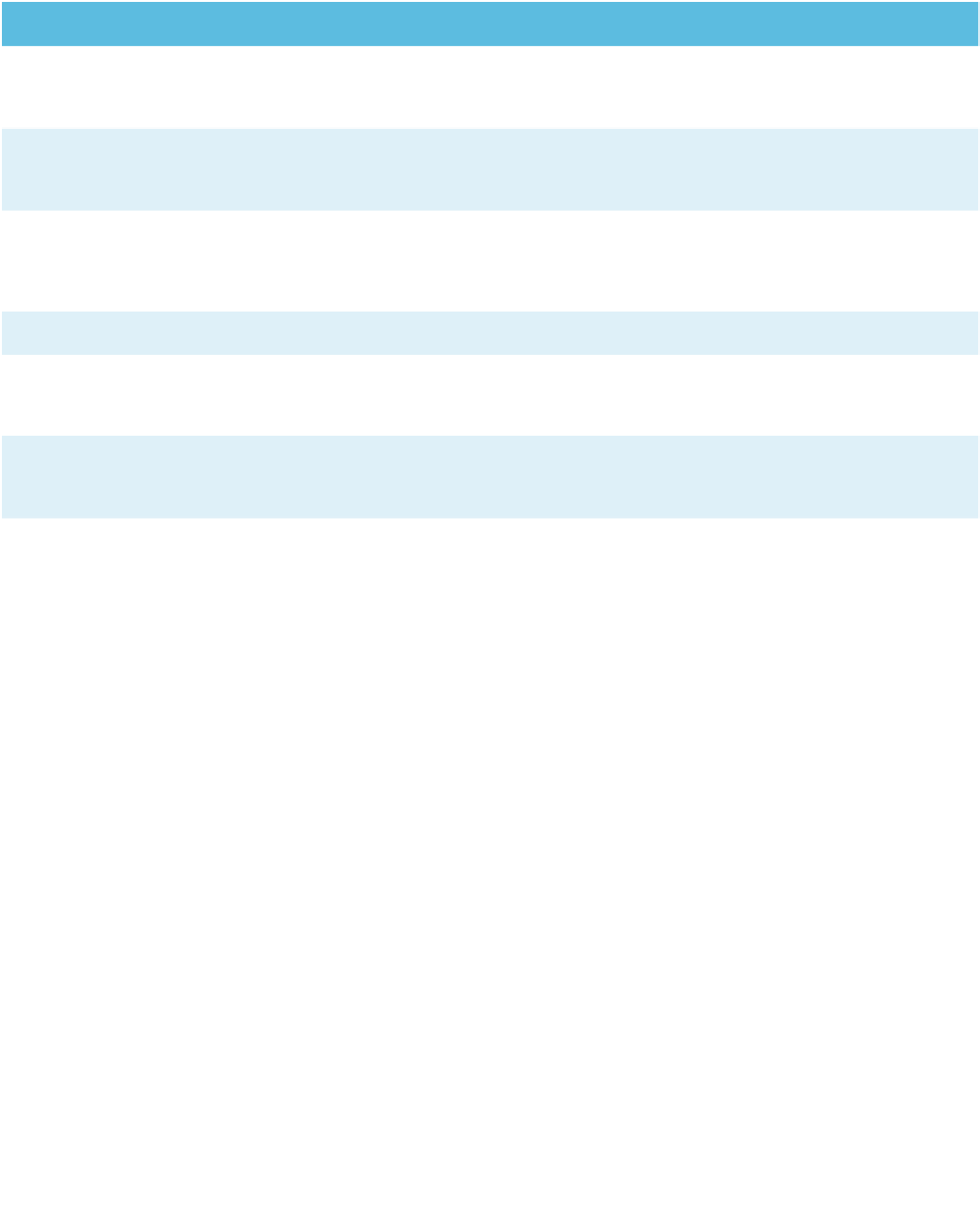

TABLE 18.4

Comparison of Surface Impoundment Embankment Types -

Increasingly, regulators, fi nancial institutions and insurers are requiring that tailings

retention structures be designed as water retention structures. Essentially, this means that an embankment needs to provide the mass, strength and sealing properties as if only

water is stored

Water Retention

Upstream

Downstream

Centreline

Mill Tailings

Suitable for any type of

tailings

At least 40-60% sand in whole tailings.

Low pulp density is desirable to

promote draining-size segregation

Suitable for any type of

tailings

Sands or low-plasticity slimes

Discharge Requirements

Any discharge proce-

dure suitable

Peripheral discharge and well-

controlled beach necessary

Varies according to design

details

Peripheral discharge of

at least nominal beach

necessary

Water Storage Suitability

Good

Not suitable for signifi cant water

storage

Good

Not recommended for per-

manent storage. Temporary

fl ood storage acceptable with

proper design.

Seismic Resistance

Good

Poor in high seismic areas

Good

Acceptable

Raising Rate Restrictions

Entire embankment

constructed initially

Less than 4.5-9 m/yr most desir-

able. Greater than 15 m/yr can be

hazardous

None

Height restrictions for indi-

vidual raises may apply

Embankment Fill

Requirements

Natural soil borrow

Natural soil, sand tailings, or mine

waste

Sand tailings or mine waste

if production rates are suf-

fi cient, or natural soul

Sand tailings or mine waste

of production rates are suf-

fi cient, or natural soul

Relative Embankment Cost

High

Low

High

Moderate

Source:

Vick (1983)

of tailings by water or wind. Upstream raising can also be carried out using waste rock or

borrow material placed on top of deposited tailings that have been allowed to desiccate.

Table 18.4

highlights the very much greater volume of embankment material required

for downstream raising compared to upstream raising, and the downstream advance of

the toe of the containment wall in downstream raising. The schematic diagrams in

Figure

walls, which may be required to ensure geotechnical stability and/or to control seepage.

Downstream construction represents the safest, most conservative approach, but also

the most expensive unless waste rock suitable for the bulk of the embankment is available

from the mine. Both upstream and centreline construction require that the deposited tail-

ings, where they will be overlain by embankment i ll, have achieved sufi cient strength to

support the imposed loads without unacceptable deformation. In practice, it is common to

undertake a geotechnical investigation to evaluate

in situ

strength properties, as a basis for

the decision as to which approach is used for the next embankment raise.

Due mainly to its low cost, upstream construction has been used for most tailings embank-

ments worldwide, until recently. However, experience indicates that upstream construc-

tion involves the highest risks. Dam failure can occur if the decant pond encroaches on the

embankment so that the phreatic surface of groundwater within the embankment rises

above the downstream toe. While the phreatic surface location is important for all types

Downstream construction

represents the safest, most

conservative approach, but also

the most expensive.

Due mainly to its low cost,

upstream construction has

been used for most tailings

embankments worldwide, until

recently. However, experience

indicates that upstream

construction involves the highest

risks.

Search WWH ::

Custom Search