Environmental Engineering Reference

In-Depth Information

tailings are thickened to high-density slurry or paste consistency using a high rate or deep

thickener or similar equipment. Conventional centrifuge pumps can pump thickened tail-

ings. Paste tailings require positive displacement pumps for their transfer. Tailings paste

plants are usually located close to the tailings discharge point.

Dry stacking of tailings, a technique pioneered by Alcoa, requires that the tailings are

de-watered to a 'cake' using vacuum belt i lters, drum i lters or similar

(

Figure 18.7

). The

cake is not pumpable and must be transferred to the disposal site by trucks or conveyor

systems. Dewatered tailings can be disposed of in engineered piles on prepared ground.

Embankments may be constructed around the perimeter of the site to collect runoff

and seepage from the pile, thus preventing it from escaping into the environment. With

cemented tailings, the thickened tailings are mixed with cement to generate a product that

is resistant to erosion and liquefaction under seismic loading.

Along the continuum of slurry, thickened, paste, dry tailings and i nally cemented tail-

ings, the solids contents and costs of production increase. However, the requirement for

large embankments reduces and the resistance to erosion and liquefaction under seismic

loading increases.

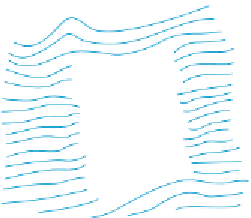

FIGURE 18.8

Typical Tailings Storage Layouts

Topographic conditions usually dictate the

confi guration of above grade tailings storages.

As with waste rock storages, additional storage

capacity can be obtained by taking advantage of

natural depressions in the landscape.

Single Ring Dike (Turkey's Nest)

Impoundment

Segmented Ring Dike (Multiple Cell)

Impoundments

Single Hill-Side

Impoundment

Multiple Hill-Side

Impoundments

Single Cross-Valley

Impoundment

Multiple Cross-Valley

Impoundments

Search WWH ::

Custom Search