Environmental Engineering Reference

In-Depth Information

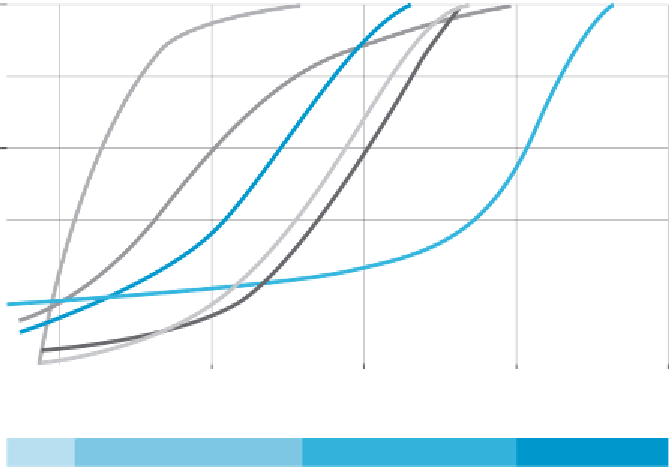

FIGURE 18.2

Particle Size Distributions for Typical

Tailings

% Finer

100

Bauxite

80

Tailings are commonly in the top three

of the following four grain size distribu-

tion groups:

1. clay - materials less than 2

µ

m;

2. silt - materials lying between 2

µ

m

to 63

µ

m;

3. sand - materials lying between

63

µ

m and 2 mm.

4. gravel - More rarely, they may

contain gravel-sized particles, more

than 2 mm in diameter.

Source:

Sarsby 2000

60

40

20

0

0.001

0.01

0.1

1

10

Particle size (mm)

Clay

Silt

Sand

Gravel

Volume of Tailings

The sheer volume of tailings creates some of the most challenging management problems

in the mining industry. The quantities of tailings produced at most precious and base metal

mines are about the same as the quantity of ore that is mined because ore grades are in the

order of a few percent at most. A high-grade gold ore body may contain tens of grams of

gold per ton (equivalent to one thousandth of 1% gold per ton) while a high grade copper

ore may contain 20 to 30 kg copper per ton (equivalent to 2 to 3 percent copper). Therefore,

even if all commercial minerals are removed, most of the original ore remains as tailings.

A mine producing 100,000 tons of copper ore per day also produces close to 100,000 tons

of tailings. This equates to several thousand truck loads per day of tailings that need to

be managed and disposed of in an environmentally acceptable manner. Where tailings are

stored and how they are managed becomes critical to determining the impacts of mining:

the larger the tailings volume the larger the associated environmental impacts and risks.

A mine producing 100,000

tons of copper ore per day also

produces close to 100,000 tons

of tailings.

Particle Size Distribution

The particle size distribution is one of the most signii cant characteristics of tailings. Prior

to ore benei ciation, most ores are i rst crushed and then milled or ground into i ne parti-

cles. The exceptions are placer gold and tin deposits, and most mineral sand ores where

the valuable minerals already occur as separate grains within essentially granular sedi-

ments. In these situations, little or no crushing or milling is required. In most other cases,

the extent of grinding required depends on the particle size of the mineral grains within

the ore. Most tailings consist predominantly of grains in the i ne sand and silt sizes (2 µm to

0.2 mm), with engineering properties similar to those of silt (Wahler and Associates 1973),

although i ner and coarser gradings are not rare.

Figure 18.2

shows particle size distribu-

tions for several tailings of contrasting particle size distribution.

For on-land disposal systems, particle size distribution is the major factor controlling

tailings deposition, consolidation and desiccation. In general terms, deposition occurs over

days while consolidation requires years or tens of years. Tailings are difi cult to drain; in

Search WWH ::

Custom Search