Environmental Engineering Reference

In-Depth Information

TABLE 17.2

(Continued)

Material Type

Geochemical Characteristics

Management Prescriptions

II

Potentially acid-forming

Low risk

3

NAG pH

4

Not suitable for construction use or general fi ll unless placed and compacted

within the core of embankments and isolated from leaching. Do not place

within 1 m of fi nal surfaces or outer edge of stockpile#.

III

Potentially acid-forming

High risk

NAG pH

3

Should be buried and isolated from leaching. Place and compact Type III materi-

als in layers. Locate material towards the centre of the stockpile area. Do not

place within 1 m of fi nal surface or within 5 m of the outer edge of the stock-

pile. Place compacted Type IC over the Type III material before placing soil cover

for rehabilitation#.

Source:

Environment Australia (1997)

EC1:2 Electrical conductivity in slurry - 2 parts water to 1 part solids

EC1:5 Electrical conductivity in slurry - 2 parts water to 1 part solids

# Type II and Type III materials can be converted to Type I material by blending with

limestone or other acid neutralizing materials.

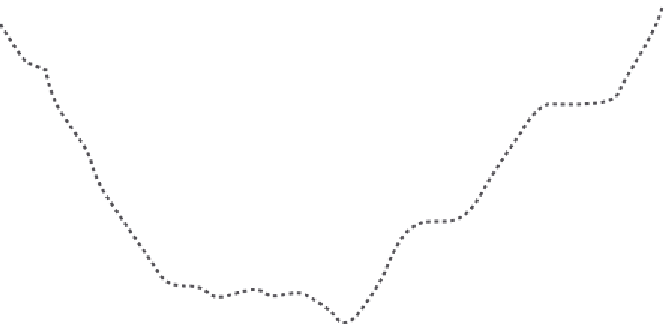

FIGURE 17.7

Cross-section Showing Block

Modelling of Acid-producing

Potential

100

50

0

RESOURCE MODEL

Drill hole

Surface

Modelled laterite

Modelled Clay

Base of strong oxidation

Oxide-transition boundary

Transition-sulphide boundary

Ore zone (

0.8g/t)

MINE WASTE BLOCK MODEL

OXIDE

UPPER MIXED

LOWER MIXED

PRIMARY

Py% - 003%

1.0 & Py%

0.3

Py% - 003%

-5.0 &

1.0 & Py%

0.3

Py% - 003%

-5.0 or Py%

0.3

Block Modelling

The results of testing and classii cation are stored in a 'block model', a 3-dimensional rela-

tional database which divides the rock mass to be mined into a series of small blocks, each

of which receives a classii cation in terms of acid-producing potential. The results can be

shown in various ways such as in cross-sections or in horizontal slices corresponding to

individual mine benches. An example is shown on

Figure 17.7

.

Search WWH ::

Custom Search