Environmental Engineering Reference

In-Depth Information

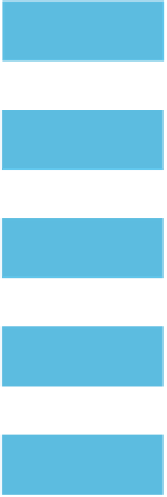

FIGURE 6.9

Countercurrent Stage-Wise Leaching

Fresh

Liquid

Spent

Solids

Stage 5

Industrial leaching processes such as

High Preassure Acid Leaching (HPAL)

apply countercurrent stage wise leach-

ing because the process can deliver the

highest possible concentration in the

extract and can minimize the amount

of solvent needed

Stage 4

Stage 3

Stage 2

Stage 1

Enriched

Liquid

Ore

6.3 THE HYDROMETALLURGICAL ROUTE AT INDUSTRIAL

SCALE

Atmospheric leaching is an operation with relatively low capital investment requirement.

This cannot be said for large industrial leaching processing plants such as the use of the

Bayer Process in alumina refining or the use of High Pressure Acid Leaching (HPAL)

processes, an emerging technology to recover nickel from laterite ore. These hydrometal-

lurgical mineral processing plants are chemical processing plants, expensive to develop and

often difficult to operate.

Rather than the single stage of atmospheric leaching, industrial tank or VAT leaching

allows countercurrent stage-wise leaching at higher pressure and/or temperature. A coun-

tercurrent stage-wise process delivers the highest possible concentration in the extract with

a minimum amount of solvent. Solvent and solid are mixed, allowed to approach equilib-

rium, and the two phases are separated. Liquid and solids move counter-currently to adja-

cent stages (

Figure 6.9

). The solvent phase (or extract) becomes more concentrated as it

contacts in a stage-wise fashion the increasingly solute-rich solid. The raffinate (leached ore)

becomes less concentrated in soluble material as it moves toward the fresh solvent phase.

The design equations comprise the overall and component material balances for the

entire process and for each separation stage. It is assumed that the solute-free solid is insol-

uble in the extracting solvent.

The total system material balance is:

A countercurrent stage-wise

process delivers the highest

possible concentration in the

extract with a minimum amount

of solvent.

(6.8)

VB

LA

VA

LB

The material balance for each component calculates as:

(6.9)

VB YB

LA XA

VA YA

LB XB

Search WWH ::

Custom Search