Environmental Engineering Reference

In-Depth Information

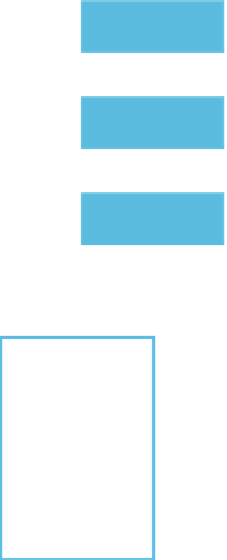

FIGURE 6.1

The Path of Copper from Mineral

to Pure Metal

Ore Mining

It is important to differentiate between

sulphide ore and leachable ore.

Generally sulphide ore is composed

of minerals containing copper, iron

and sulphur, hence the name sulphide.

Leachable ore is composed primarily

of minerals containing copper oxide.

Comminution

Concentrating

Leaching

Extraction

Roasting

Stripping

Smelting

Electrowinning

Conversion

Anode Casting

Electro-Refining

Final Copper

Cathodes

6.1 THE USE OF FIRE - PYROMETALLURGICAL MINERAL

PROCESSING ILLUSTRATED

In pyrometallurgy, concentrated copper ore is smelted and refined. The use of fire (pyro in

Greek) to extract metals pre-dates recorded history, and it remains the conventional and

most commonly used metallurgical process: reactions are faster at higher temperatures;

molten metals are easy to handle and alloy; reagents (fluxes) are cheap; the metal and

impurities separate easily; the precious metals stay with the primary metal; and the con-

centration of copper in a smelter is 20 times that in a hydrometallurgical process (Dresher

2001). Due to the high recovery rate the process remains especially attractive for high

grade ores when even a small increase in recovery results in a substantial increase in profit.

It would surprise most people, even those involved in the industry, that smelting and refin-

The use of fi re to extract metals

pre-dates recorded history, and

it remains the conventional

and most commonly used

metallurgical process.

Search WWH ::

Custom Search