Environmental Engineering Reference

In-Depth Information

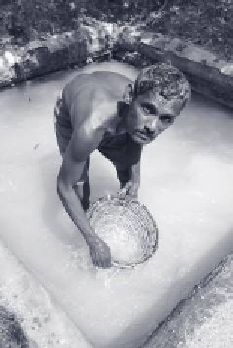

FIGURE 5.3

Seabed Mining near the South-West

Coast of Africa, and Traditional Mining

by Hand

Eroded from kimberlite, diamond

becomes an ideal placer mineral in

streambeds and in beach and coastal

sands and gravels. Vacuum devices are

used to excavate diamonds-bearing

sediment from sea bed placer deposits.

Photo Credits:

www.debeersgroup.com

Ira de Reuter 2007 (photo to the right)

extensively applied in Northern European countries to generate fuel for more than 100

peat i red power plants, is closely related to coal mining.

Although coal and petroleum would not be classii ed by chemists as minerals, they are

frequently referred to as fuel minerals in the mining industry (

Case 5.5

). It may also be

argued that groundwater should be considered as a mineral, and groundwater abstraction

should consequently be subject to mining legislation. However, the main distinction here is

that groundwater is (usually but not invariably) a renewable resource, which is harvested,

rather than mined. The exploitation of petroleum and gas, while originating from min-

ing, has evolved into a separate highly specialized discipline involving technologies quite

different from those used in mining. Oil and gas extraction will not be further discussed

in this topic. However, it will become apparent that many of the environmental and social

issues associated with mining are similar to issues faced by the oil and gas industry.

Many of the environmental and

social issues associated with

mining are similar to issues faced

by the oil and gas industry.

CASE 5.5

Oil Sand Mining in Canada

Nothing demonstrates the blurred boundary between fossil

fuels and minerals extraction better than oil sand mining in

Canada, home of large oil sand deposits. The vast majority

of Canada's oil sands are located in Alberta, where they

underlie an area larger than Florida. Canada's oil sands are

the second single largest hydrocarbon deposit on Earth,

second only to the vast oil resources in Saudi Arabia. While

this resource is next door to the biggest market for oil

products, the USA, large-scale development started less than

10 years ago. Why? The costs of extracting oil from sand

are tremendous. Depending on the depth of the reserves,

oil sands are either surface mined from open pits (strip

mining) or heated so the bitumen can fl ow to a well and

be pumped to the surface (in situ extraction). On average

it requires two tonnes of oil sand to produce one barrel of

oil. Crude bitumen is extracted from the mined oil sands

through a process that essentially mixes the oil sands with

hot water to wash the bitumen from the sand. Producing

the fi nal synthetic crude oil from bitumen requires two

further stages of upgrading, hydro-cracking and hydro-

treating. Synthetic crude oil is then refi ned to the fi nal

petroleum products.

Source: Woynillowicz et al. 2005; Photo Credit: Melina

Mara 2005, The Washington Post

Search WWH ::

Custom Search