Environmental Engineering Reference

In-Depth Information

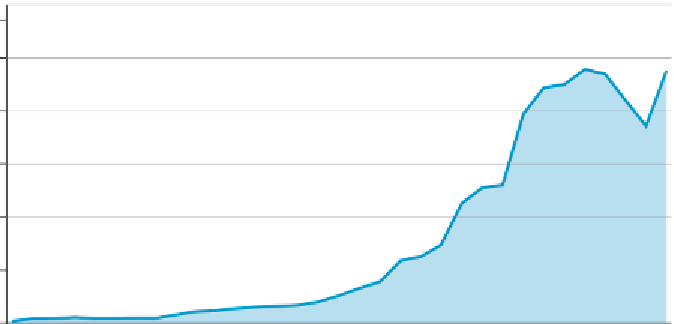

FIGURE 4.10

Increase of Production Rate over Mine

Life Illustrated

300

250

From an initial production rate of

less than 20,000 tons per day of

ore in early 1970, Freeport's mining

operations in the Papua Province of

Indonesia now extract copper and

gold bearing ore at a staggering rate of

more than 250,000 tons per day, which

equates to more than 90 million tons

each year. In comparison, most

mid-sized gold mines process about

1 million tons of ore per year.

200

150

100

50

0

faster to achieve. Secondly, exploration continues during the mine operation and addi-

tional mineable ore reserves may be discovered. For the purpose of environmental permits,

it is often advisable to obtain the permit for a realistic but upper limit of ore production

rates. The environmental permit remains valid if actual ore production rates are below the

approved ore production rate; a new environmental approval however may be required if

actual rates signii cantly exceed the approved design rate.

Ore production rates largely depend on the mining method employed. The depth of

a particular deposit determines whether it will be extracted by surface mining, in which

minerals or coal are extracted directly at the surface, or underground mining, in which

deposits are too deep to be economically removed by surface mining (

Figure 4.11

)

. Surface

mining is more common, since it is less expensive than underground mining. Hence, only

high ore grades normally warrant underground mining.

At this point some semantic difi culties relating to the size of a mine operation need to

be examined. Depending on the point of view, various means of referring to the size of

operations are common, as illustrated in

Table 4.3

for a hypothetical copper mine opera-

tion. For example, the mine superintendent thinks in terms of material moved, while the

mill superintendent cares about the amount of ore processed per day. Top management

thinks in terms of copper equivalent per year. The i gures in

Table 4.3

are based on a mine

producing 100,000 tons of copper per year from copper ore with an average grade of 0.5

percentage, and with an average stripping ratio 2 to 1. In most circumstances, however,

mine size is expressed as tons per day of processed ore.

A new environmental approval

may be required if actual rates

signifi cantly exceed the approved

design rate.

In most circumstances mine size

is expressed as tons per day of

processed ore.

Benefi ciation

Excavating ore from the Earth is only half the battle since the required products are rarely

found in their pure form. More often they are mixed with rock and gangue minerals, and

usually as compounds of several elements. Some minerals yield their elemental constituents

more readily than others. Therefore the economic viability of an ore deposit depends not

only on the quantity and quality of accessible ores, but also on the ease with which valuable

metals can be extracted from gangue materials (schematically illustrated in

Figure 4.12

for

pyro-metallurgical copper extraction). Mineral extraction from ore conventionally takes

place in mills (ore dressing or benei ciation), smelters (converting concentrates to metals),

and rei neries (producing the i nal high grade products as required by the market).

Ore benei ciation is the processing of ores to regulate the size of the product, to remove

unwanted constituents, or to improve the quality, purity, or grade of a desired product.

Search WWH ::

Custom Search