Environmental Engineering Reference

In-Depth Information

simple in concept, the dei nition of the cutoff grade for a particular mine is challenging and

open to discussion and interpretation.

From the perspective of the host country, which usually retains ownership of an ore

deposit, the cutoff grade should be as low as possible to maximize the amount of miner-

als mined or to achieve maximum resource utilization. From the perspective of the mine

investor, the best cutoff grade is the one that produces the highest return on investment.

This can and does in many cases mean that much of the mineral deposit remains unmined,

either temporarily until prices improve, or permanently if prices never increase sufi ciently

to justify extending or re-opening the mine. Discrepancies in dei ning an appropriate

cutoff grade exist and, to some extent, the environmental assessment of a mine proposal

needs to elaborate the different factors that have inl uenced the dei nition of a particu-

lar cutoff grade. A critical review of a chosen cutoff grade, of course, is well beyond the

scope of the environmental assessment, as well as the expertise of environmental special-

ists. Nevertheless, since the cutoff grade will inl uence the footprint of the mine, the vol-

ume and type of waste produced, and the life of the project, it represents a major factor in

determining the environmental impacts of a mining project.

In general, the cutoff grade will fall when project borrowings have been repaid, and

near the end of a project when many of the project operations have been curtailed.

Recognizing this likelihood, many operators segregate and stockpile low grade mined

material with the intention of processing it after mining has been completed, providing

that this can be done economically. This practice introduces its own uncertainties in envi-

ronmental management. Should the low grade material be managed as waste rock, sub-

ject to whatever management strategies apply, or should it be assumed that the low grade

stockpile will ultimately be processed? This is of particular importance in many suli de

deposits as the low grade stockpile may contain much higher concentrations of potentially

acid-generating materials than the waste rock.

From the perspective of the

mine investor, the best cutoff

grade is the one that produces

the highest return on investment.

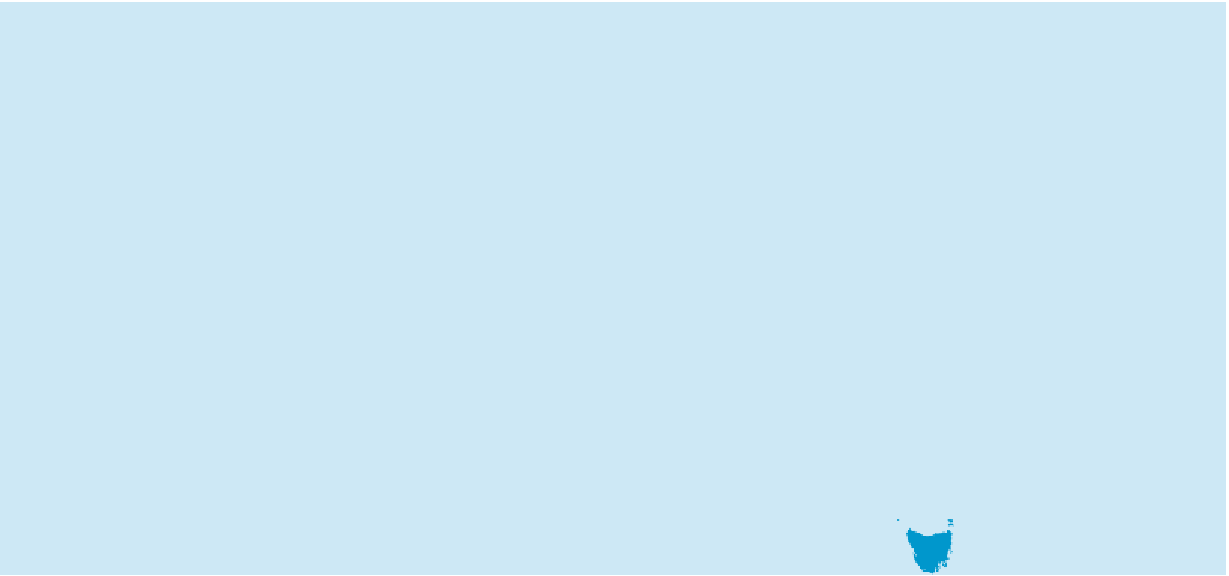

CASE 4.2

Effects of Location on Cutoff Grade

Gove

Darwin

Weipa

Bauxite, the major ore of aluminium, was discovered in the

Darling Range region of Western Australia more than

50 years ago. However, the average grade of Darling Range

bauxites proved to be much lower than in most other

bauxites mined at the time. Despite aluminium contents

generally up to 20% lower than those in other bauxite

mining areas such as Jamaica, the Darling Range bauxite

mines and associated alumina refi neries emerged as some

of the world's lowest cost producers of alumina. The

main reason for this is the location of the Darling Range

bauxite deposits in a region close to infrastructure includ-

ing ports and towns, and with a skilled workforce located

nearby. The three alumina projects developed by Alcoa

(Kwinana, Pinjarra and Wagerup) together with the Worsley

Alumina Project, established Australia as the world's leading

source of alumina (AAC 2006).

NT

Gladstone

QLD

WA

Brisbane

SA

NSW

Perth

Newcastle

Sydney

ACT

Adelaide

VIC

Melbourne

Bauxite Mines

Portland

Geelong

Alumina Refineries

Alumina Smelters

Bell Bay

TA S

Search WWH ::

Custom Search