Environmental Engineering Reference

In-Depth Information

Today's deposits are usually of

large tonnage and low grade,

mined in bulk, and referred to as

bulk low-grade deposits.

low grade, mined in bulk, and referred to as bulk low-grade deposits. The largest such

deposits are referred to by the industry as 'elephants'.

The cutoff grade allows one to calculate the enrichment factor, the multiplier by which

the average concentration of a particular element must be increased to become economi-

cally mineable (

Figure 4.3

)

. Each mineral or metal has its own enrichment factor, which

represents a balance between the price of the material and its average abundance in the

Earth's crust. In general, the enrichment factor is greatest for metals that are least abun-

dant in the crust, such as gold or mercury. Rather surprisingly however, gold, even though

one of the scarcest mined elements, does not rank at the top of the list - mercury does. If

the price of a particular metal falls, it requires an even higher enrichment factor for the

metal to be economically extractable. On the other side, due to technological advances in

i nding and mining ores, some deposits that are now considered as ore are well below the

lowest grade ores some decades ago.

Three observations emerge from the above discussion. Firstly, the search for an ore

deposit is comparable to the search for the proverbial needle in the haystack. Even after a

mineral deposit has been discovered after lengthy prospecting and exploration, only 1 out of

1,000 mineral deposits eventually evolves into a mine (Roscoe 1971). Secondly, with very few

exceptions, mining requires the excavation of a large volume of rock and Earth materials of

which only a small percentage of volume is extracted as mined minerals. The remaining

materials have to be discarded as waste close to the mine. In fact the placement of unwanted

materials imposes the biggest direct environmental impact of any mine. Thirdly, the

cutoff grade is one of the most important numbers in the mining industry. Although

The search for an ore deposit is

comparable to the search for the

proverbial needle in the haystack.

The cutoff grade is one of the

most important numbers in the

mining industry.

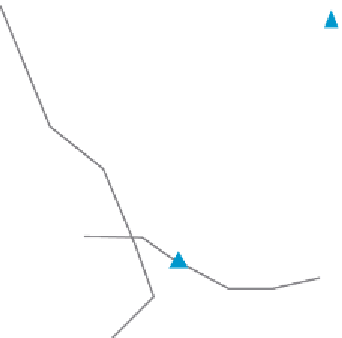

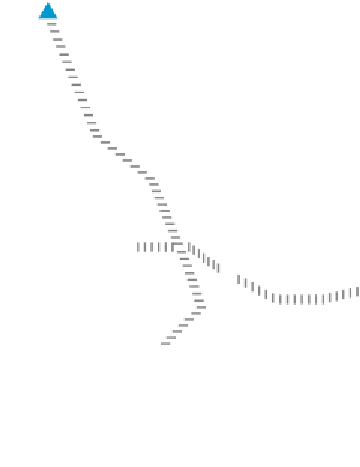

Dampier

AUSTRALIA

Perth

CASE 4.1

Tom Price Iron Ore Mine in Australia

Sydney

Iron ore was discovered in the Pilbara region of Western Australia in the 1800s,

but despite geologists claiming there was enough to supply the whole world, the

remoteness and ruggedness of the country stopped people from initially exploiting

the deposits. The historic moment in the discovery of one of the world's richest

iron ore bodies came in 1962, when two CRA geologists found a large dark out-

crop which extended about 6.5 kilometres, later to be known as Mount Tom Price,

in tribute to an American engineer who was instrumental in the Pilbara's develop-

ment. Production at Mt Tom Price began in 1966, four years after the discovery

of this huge hematite deposit. Today ore from this mine is still an important part

of the Hamersley Range mining: the chemical and physical quality of Mt Tom Price

lump and fi nes is outstanding with iron content well above 60 percent.

Dampier

NORTH

Railway

Brockman

Marandoo

Source: Hamersley Iron - Technical Fact Book.

Mount Tom Price

Yandicoogina

Paraburdoo

Channar

Search WWH ::

Custom Search