Environmental Engineering Reference

In-Depth Information

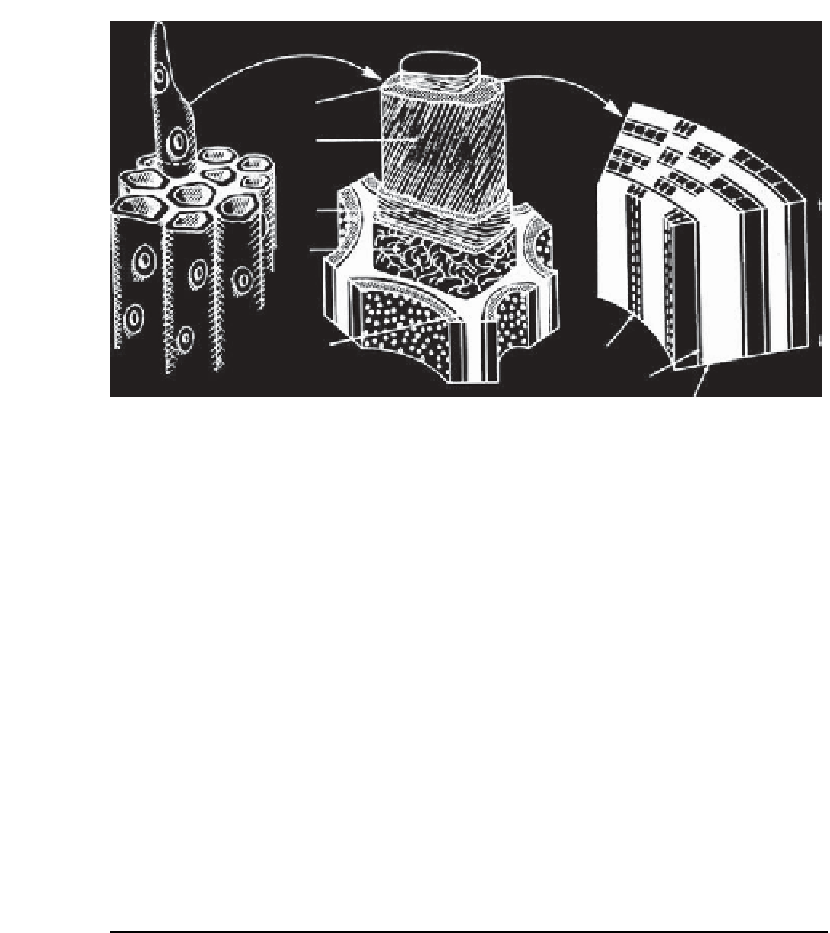

S3

S2

S1

P

M.L.

Cellulose ibrils

Hemicellulose

Lignin-Hemicellulose

matrix

FIGURE 2.6

Schematic illustration of the molecular architecture of wood tissue, showing

the relationship of contiguous cells (left), cutaway view of the cell wall layers (center), and

one depiction (from Goring, 1977) of the relationship of the lignin, hemicelluloses, and

cellulose in the secondary wall. Recent evidence suggests a more intimate admixture of the

lignin and hemicelluloses than illustrated here (R. Atalla, personal communication.) The

diameter of each cell is approximately 25

μ

m. S1-S3, secondary cell wall layers; P, primary

wall; and M.L., middle lamella. (Source: Reproduced with permission from Kirk and Cullen

(1998). © John Wiley & Sons.)

TABLE 2.4 Chemical composition of common lignocellulose feedstock (db)

Cellulose

(wt%)

Hemicellulose-derived

C

6

sugars (wt%)

Hemicellulose-derived

C

5

sugars (wt%)

Lignin

(wt%)

Biomass type

Softwood

40-48

12-15

7-10

26-31

Hardwood

30-43

2-5

17-25

20-25

Cereal straw

38-40

2-5

17-21

6-21

Maize straw

35-41

2

15-28

10-17

Rape straw

38-41

—

17-22

19-22

Recovered paper

50-70

—

6-15

15-25

Adapted from Kamm et al. (2006).

food and animal feed (e.g., olive or sunflower oil, animal fats, and sucrose from sugar-

cane) but also as lubricants, rubbers, pharmaceuticals (e.g., antibiotics and vitamins

synthesis), dyes, and even cosmetics (e.g.,

Jojoba

oil) (Biermann et al., 2006; Kripp,

2006). They are also used as feedstocks for many first-generation biofuels based on

vegetable oils. When associated with the use of the edible part of the plant only for

energy carrier generation, the product is called a first-generation biofuel.

Search WWH ::

Custom Search