Environmental Engineering Reference

In-Depth Information

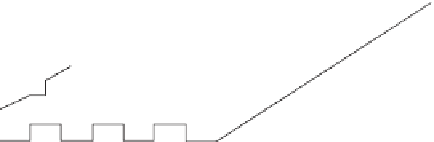

Current low

End plate

Anode

Electrolyte

Cathode

Repeating unit

Oxidant low

Anode

Bipolar

separator

Fuel low

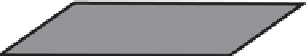

FIGURE 16.2

A typical planar SOFC configuration. (Source: Reproduced with permission

from Stambouli and Traversa (2002). © Elsevier Science Ltd.)

can be used as cathode materials for SOFCs because of the high operating temperature.

Noble metals are not desirable for practical applications because of their prohibitive

cost and insufficient long-term mechanical stability. Perovskite-type lanthanum

strontium manganite (LSM) provides excellent thermal expansion matching with

zirconia electrolytes and performs well at operating temperatures above 800

C.

For operation at lower temperatures, mixed ionic/electronic conducting ceramics,

such as the perovskite lanthanum strontium cobalt ferrite (LSCF), are under serious

consideration. Currently, several new cathode materials are under development for

SOFCs, but a detailed description of such materials is beyond the scope of this topic.

The reader is referred to the overview works of Skinner (2001) and Jacobson (2010).

16.2.5 Stack Design

To reach sufficient power levels, FC are interconnected to form stacks. There are dif-

ferent stack design concepts based on tubular and flat-plate cells. Figure 16.2 shows a

planar SOFC configuration. Interconnects, which are made of ceramic or metallic com-

pounds depending on the operating temperature, connect the cells within the stack.

In comparison to planar designs, tubular designs do not require a specific seal to

isolate the oxidant from the fuel, which makes the performance of the tubular cell

highly stable over long-term operation. A schematic view is presented in Figure 16.3.

16.3 BIOMASS GASIFIER-SOFC COMBINATION

Considering biosyngas as a fuel for use in SOFCs raises many critical issues. One sig-

nificant task is to define the tolerance limits of the anode for contaminants such as tar,

Search WWH ::

Custom Search