Environmental Engineering Reference

In-Depth Information

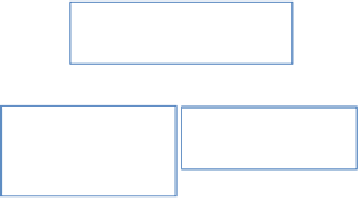

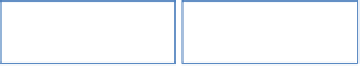

Municipal solid waste

(MSW, 1000 kg)

Metals

(

30 kg

)

Refuse derived

fuel (

420 kg

)

Organic fraction

of MSW

(OFMSW,

400 kg

)

Paper/plastic

(

150 kg

)

Washing

Sand (

39 kg

)

Biodegradable

OFMSW (

261 kg

)

Coarse inerts

(

100 kg

)

AD

Biogas

(

137 m

3

)

Digestate

(

162 kg

)

Process water

(

162 kg

)

FIGURE 14.11

Typical mass balance for a MSW treatment plant including anaerobic

digestion (AD) of the biodegradable organic fraction. This example is based on the Vagron

plant for treatment of 230,000 tonnes MSW per year, located in Groningen.

Depending on the quality and potential local application of the digestate, it will

require several postprocessing steps. Usually, these processing steps involve

phase separation resulting in a nutrient-rich liquid fraction and a solid fraction

that after drying is suitable for combustion in a power plant. Nutrient removal

or recovery strategies are available for treatment of the liquid fraction of the

digestate.

Utilization of the biogas for electricity and heat production requires the construc-

tion of a CHP plant.

In the following paragraphs, some integration aspects of the anaerobic digestion proc-

ess will be discussed.

14.4.3.1 Biogas Upgrading and Utilization

Biogas is composed of methane

(CH

4

) and carbon dioxide (CO

2

) with smaller amounts of hydrogen sulfide (H

2

S),

ammonia (NH

3

), and dinitrogen gas (N

2

). Usually, biogas is saturated with water

vapor. In principle, biogas can be used for all applications designed for natural

gas. Not all gas applications require the same gas standards.

For utilization of biogas in a CHP, hydrogen sulfide needs to be removed in order

to avoid corrosion of the boiler due to sulfuric acid (H

2

SO

4

) production by oxidation

Search WWH ::

Custom Search