Environmental Engineering Reference

In-Depth Information

Ethanol recovered

from scrubber

Recycle

Dehydrated

ethanol

Molecular

sieve

Distillation

Hydrated

ethanol

Clariied

wine

Vinasse (bottom)

Fusel oil (side stream)

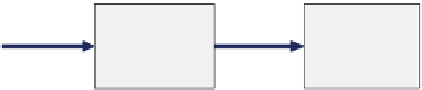

FIGURE 13.6

Purification.Aseries of distillations yields 96 vol.% ethanol, and molecular

sieve adsorbs the remaining4vol.% water.

Exhaust gas

Hot

lue gas

Bagasse

from mills

Ash

Bagasse

drying

Cogeneration

Dry

bagasse

Air

Bagacilho for ilter aid

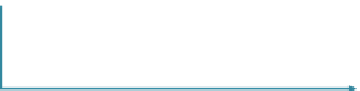

FIGURE 13.7

Cogeneration of electricity.Before incineration, the wet bagasse is dried using

the hot flue gas.Note that the diagram just gives the mass flows but that electricity is the most

important product of the cogeneration.

TABLE 13.2 Glossary for the bioethanol process

Ash Minerals (salts) remaining after combustion

Bagacilho Dried bagasse

Bagasse Remainder of sugarcane plant after pressingjuice, mainly polysaccharide

from cell walls

Filter aid Inorganic powder (e.g., silica) which, on a filter,prevents clogging

Fusel oil Mixture of C

3

to C

5

alcohols and other volatile side products of

fermentation

Imbibition Replacement of interstitial liquid by water

Lime Calcium oxide (CaO) or calcium hydroxide (Ca(OH)

2

)

Molecular sieve Material with nanopores in which water fits (e.g., aluminosilicate crystals)

Mud

Aqueous mass containing ~20 wt% undissolved polymer

Sucrose

Plain sugar, a disaccharide of the monosaccharides glucose and fructose

Vinasse

Water fraction (impure) from ethanol distillation

Wine

Aqueous ethanol solution, centrifuged after fermentation

Search WWH ::

Custom Search