Environmental Engineering Reference

In-Depth Information

10

1st condenser

2nd condenser

8

6

4

2

0

0 0 0 0 0 0

Temperature of 1st condenser (°C)

60

70

80

90

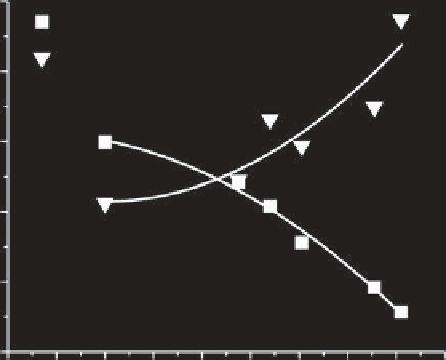

FIGURE 11.11

Staged condensation; acetic acid distribution over the first and second

condenser. The reactor temperature is 480

C. The second condenser operates at 20

C.

Spray columns are used. (Source: Reproduced with permission from Westerhof et al.

(2011). © American Chemical Society.)

11.8 CATALYTIC PYROLYSIS

Catalytic pyrolysis has been considered to overcome the problematic characteristics

of pyrolysis oil, as mentioned in the introduction, and to more selectively produce

target compounds. Impregnating specific compounds such as H

2

SO

4

and ZnCl

2

into

the biomass particles in order control the primary reactions and the use of heteroge-

neous catalysts in the reactor to steer the secondary reactions have received signif-

icant attention in the last years. This section is not intended to give a detailed account

of catalytic pyrolysis, but merely to mention its scope. Dickerson and Soria (2013)

listed and reviewed the developments. Selective oxygen removal from the pyrolysis

vapors, preferably by decarboxylation, aiming at increasing the heating value and

decreasing the acidity of bio-oil, has been studied most. Deoxygenation reactions

are catalyzed by acids, and the most studied ones are solid acids such as zeolites

and clays. Aiming at the production of chemicals, yields of aromatics of ca. 20% (car-

bon basis) when using modified ZSM-5 zeolites have been reported (Cheng et al.,

2012). All reported results on catalysis to steer the heterogeneous reactions show that

low product yields and excessive coke and water formation are still items that need

considerable attention.

The company KiOR (United States; see Internet References) developed a fluid cat-

alytic cracking (FCC)-like catalytic pyrolysis process. Not much detailed information

is available about this process. However, patent information available indicates the

use of alkali and alkaline earth catalysts on mildly acidic support oxides such as

Search WWH ::

Custom Search