Environmental Engineering Reference

In-Depth Information

not evident that at these lower temperatures also high concentrations of organic

matter can be treated. This subsection is focused mainly on gasification, without

or with catalysis, at about 600

C.

2.

High Pressures.

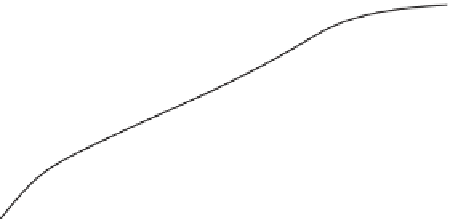

It is crucial for the process that the heat content of the reactor

effluent is utilized as far as possible to preheat the feedstock stream (mainly

water) to reaction conditions (see Figure 10.10). However, heat exchange

between these streams is not practical at low pressure, because of the high heat

of evaporation at nearly isothermal and isobaric conditions. Heating of the feed-

stock stream to the desired gasification temperatures in a heat exchanger with-

out evaporation requires operation at high pressures. This is the true incentive of

the high pressures involved in wet gasification. The efficiency of the heat

exchange in relation to the applied pressure can be calculated from the heat bal-

ance for a countercurrent shell and tube heat exchanger. The result is presented

in Figure 10.13, in which the heat exchanger efficiency is plotted as a function

of the operating pressure and the available area per unit throughput. In case of

an infinite surface area (no overall transport limitations), the efficiency is

given by

H

vap

H

hot

,

in

−

Δ

η

HE

=1

−

ð

Eq

:

10

:

20

Þ

H

cold

,

in

1.0

∞

100

0.9

50

0.8

25

0.7

0.6

A

HE

= 10

0.5

0.4

0.3

0.2

H

cold,out

-

H

cold,in

Supercritical

pressure

η

HE

=

0.1

H

hot,out

-

H

hot,in

0.0

0

5

10

15

20

25

30

35

Pressure (MPa)

FIGURE 10.13

Calculated efficiencies of a water

water countercurrent heat exchanger

plotted versus the operating pressure for different surface areas; AHE = area (m

2

) per unit

throughput (kgs

−1

). The flow rates (kg

-

s

−1

) on both sides were assumed to be equal. U =

1000 Wm

−2

K

−1

). Inlet conditions: T

hot,in

= 600

C, and T

cold,in

=25

C.

Search WWH ::

Custom Search