Environmental Engineering Reference

In-Depth Information

nontransferred torches, the position of the arc is within the torch, and plasma is estab-

lished in the gas flowing through the device.

10.4 GASIFICATION IN AN AQUEOUS ENVIRONMENT:

HYDROTHERMAL BIOMASS CONVERSION

10.4.1

Introduction

Although wet biomass has a very low overall heating value, still products with a high

heating value can be extracted from it by applying advanced conversion processes.

Gasification in hot compressed water is considered a promising technique to convert

such wet streams into medium calorific gas. The produced gas is rich in either

hydrogen or methane depending on the operating conditions and applied catalysis.

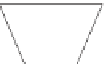

By practicing countercurrent heat exchange between the feed stream and the reactor

effluent (see Figure 10.10), high thermal efficiencies can be reached despite the low

dry matter content of the feedstock. Apart from this essential energetic benefit, the

unique properties of hot compressed water are believed to be beneficial for the desired

chemistry. It promotes ionic reaction pathways over radical routes, leading to less char

formation. Generally, organic molecules are reactive in pressurized water at tempera-

tures above 250

C.

H

2

-rich gas

LP G/L

separator

Reactor

Feed tank

Water

Biomass/

water

CO

2

-rich gas

HP G/L

separator

Heat exchanger

LP G/L

separator

Feed pump

Water

FIGURE 10.10

Simplified process scheme of the PDU for SCWG in Enschede,

the

Netherlands.

Search WWH ::

Custom Search