Environmental Engineering Reference

In-Depth Information

Raw

biosyngas

Raw

biosyngas

Cyclone

Cyclone

Freeboard

Gas phase

reactions

Gas phase

reactions

Circulating

luidized bed

Fly ash and

particles

Fuel

Additional

sand

Fuel

Additional

sand

Bubbling

luidized bed

Velocity

5-10 m/s

Velocity

2-3 m/s

Inert + char

Bottom ash and

bed material

Bottom ash and

bed material

Grate

Grate

Fluidization

medium

Fluidization

medium

Raw biosyngas

Flue gases

Fuel

Additional

sand

Velocity

5-10 m/s

Velocity

5-10 m/s

Bottom ash and

bed material

Bottom ash and

bed material

Grate

Steam

Air

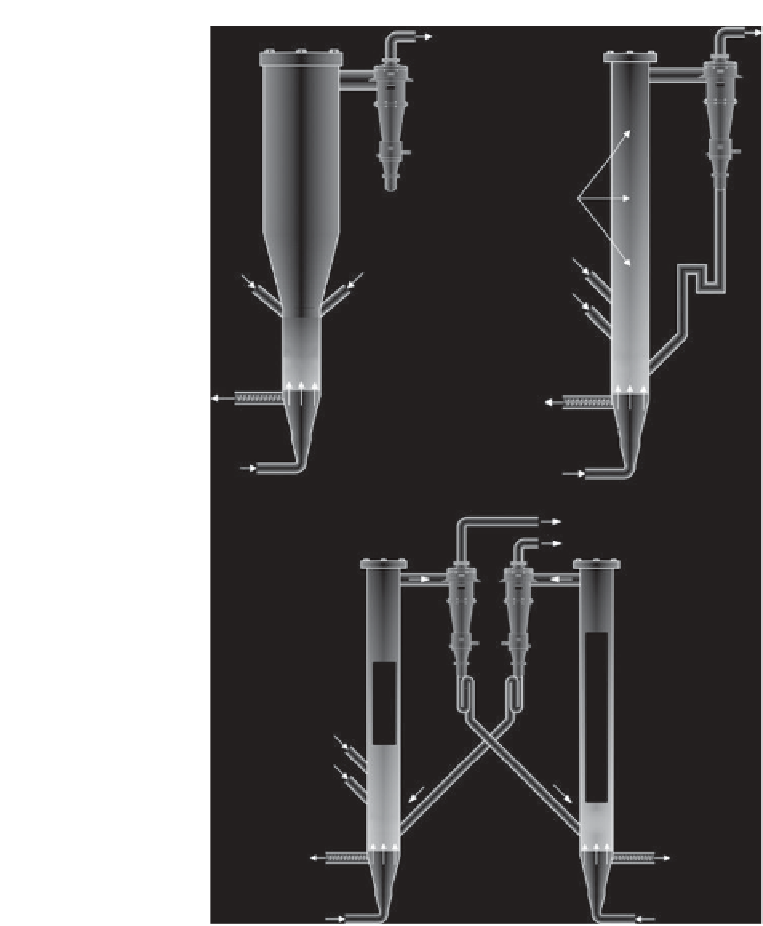

FIGURE 10.9

Configurations of fluidized bed reactors: BFB (top left), CFB (top right), and

interconnected (indirect) fluidized beds (bottom). (Source: Adapted with permission from

Olofsson et al. (2005). © Umeå University (Sweden).)

process is well above 90%, due to the high residence time of the biomass particles and

the residual conversion when entrained to the freeboard. The tar content of the gas is in

between the tar content of the downdraft and updraft gasifiers. An example of a BFB

design is the steam-/oxygen-blown gasifier developed by IGT, now commercially

manufactured by Carbona.

Search WWH ::

Custom Search