Environmental Engineering Reference

In-Depth Information

Fuel

Fuel

Fuel

Syngas

Drying

Drying

Drying

Pyrolysis

Pyrolysis

Pyrolysis

Reduction

Syngas

Air

Air

Reduction

Oxidation

Air

Hearth

Oxidation

Reduction

Ash

Air

Syngas

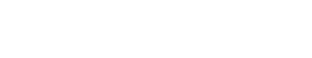

FIGURE 10.8

Diverse fixed bed reactor types: updraft (left), downdraft (mid), and cross-

draft (right). (Source: Adapted with permission from Olofsson et al. (2005). © Umeå

University (Sweden).)

(see Figure 10.8). Typically, such gasifiers are coupled to diesel or gas engines; sys-

tems of 100

200 kW

e

with an approximate electrical efficiency of between 15 and

25% are commercially available on the market. High costs and the need for gas clean-

ing and careful operation have prevented application in large numbers. Some systems

are being applied more or less successfully in, e.g., rural areas of India, Indonesia, and

China (Stassen, 1995).

The

downdraft gasifier

is a cocurrent reactor, in which the fuel and the gasification

agent move in the same direction, and it is presented in Figure 10.8 (mid). Different

distinct reaction zones are present in this reactor type: a drying zone in which

moisture is evaporated from the biomass fuel while slowly moving downward in

the direction of the pyrolysis zone; in that zone, the biomass is decomposed into

chars, tars, and gases. A part of the pyrolysis gas/vapor products is burned in the

combustion zone below. The heavier (polyaromatic) hydrocarbon species, called tars,

are cracked there due to the high temperature, which is a result of the overall exother-

mic reactions in the combustion zone. Thus, the produced gas exiting from below

the last gasification zone is relatively clean, i.e., with low tar concentrations. In

the gasification zone, remaining char is converted using the steam and carbon dioxide

in the gas from the combustion zone above that has run out of oxygen. This gasifier

configuration is uncomplicated and practically mostly reliable and has been proven

for quite some biomass fuels, such as relatively dry blocks or lumps with a low ash

content and containing a low portion of fine and coarse particles (Bridgwater, 1995).

The physical limitations of the diameter in relation to the particle size mean that

there is an upper limit to the capacity of this configuration of around 500 kg

−

h

−1

(Bridgwater, 1995).

Another alternative fixed bed gasifier design is the

updraft gasifier

, which is a

countercurrent reactor in which the fuel and the gasification agent flow in opposite

directions. In Figure 10.8 (left), a schematic representation of an updraft gasifier is

Search WWH ::

Custom Search