Environmental Engineering Reference

In-Depth Information

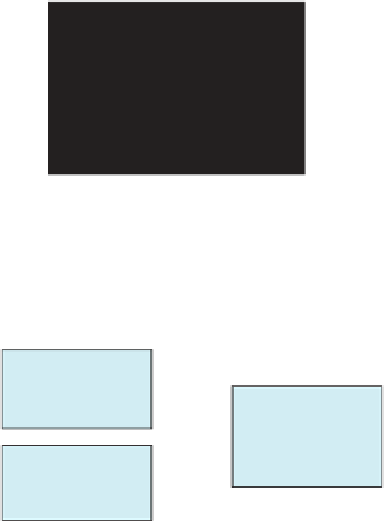

Input-output diagram of process

Preferred technologies

and license(s)

Process boundary

“battery limit”

Co-feed

Fuels

Oxygen

Biomass to energy

Heat

carrier

Reference

process

Power

Syngas

PROCESS

Biomass

Auxiliary

chemicals

(solvents, catalyst, etc.)

Wastes: G / L / S

Utility system

Syngas (1)

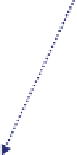

Co-feed

Fuels

Heat

Power

Subprocess 1

Oxygen

Subprocess 3

Subprocess 2

Syngas (2)

Biomass

FIGURE 7.8

Splitting a process into subprocesses.

3. Reversely, the intermediate product can be imported if the demand of sub-

process 3 exceeds the joint production capacity of subprocesses 1 and 2. In this

example, the syngas going to subprocess 3 is converted into three products:

liquid fuels, power, and heat.

d.

Analysis and (e) Evaluation

These are done for each alternative in the same way as for the full process, end-

ing with (f )

Selection

and (g)

Documentation

of the better options for propa-

gation to the next level of design.

7.8 PROCESS DESIGN: FUNCTIONAL BLOCK DIAGRAM

Design at the third level generates a network of processing functions, encapsulated in

process units. The focus here is on which functions are needed and how they interact

in the network for an optimal performance. Targets are derived for the functional

Search WWH ::

Custom Search