Environmental Engineering Reference

In-Depth Information

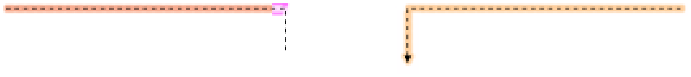

Preferred technologies

and license(s)

Permits

Capital (investment)

Up-time/year

Production mode(s)

Oxygen carrier

Biomass

+ co-feed

Energy products

PROCESS

•

Which co-feed

•

Supply/year

•

Quality consistency

•

Supply dynamics

•

Price ranges

•

Suppliers

•

Which products

•

Demand/year

•

Quality

•

Demand dynamics

•

Price ranges

•

Customers

Design

speciications

Auxiliary chemicals

(solvents, catalysts, ...)

Process boundary

Waste (L/S), emissions (G)

Utility system

(water, steam, power, fuel)

FIGURE 7.7

Input-output diagram of a process as a basis for design.

the oxygen content by putting air through a cryogenic air separation unit with

partial or nearly complete removal of nitrogen. The cost of enriched air is signif-

icant but one saves much on investment cost by having a more compact process.

Thirdly, oxygen from the water molecules in steam can be used for conversion, as

is done for reforming reactions in the gas phase:

CH

x

O

y

+H

2

O

!

ð Þ

1

−

y

CO+

y

CO

2

+1+

x

ð

=

2

Þ

H

2

ð

0

≤

y

<1;0

≤

x

≤

4

Þ

ð

RX

:

7

:

1

Þ

Fourthly, in dry reforming, the oxygen atoms in carbon dioxide are exploited:

CO

2

!

CH

x

O

y

+1

ð Þ

−

y

ð Þ

2

−

y

CO+

x

ðÞ

=

2

H

2

ð

0

≤

y

<1;0

≤

x

≤

4

Þ

:

:

ð

RX

7

2

Þ

In all four situations, the reverse water

gas shift (WGS) reaction and the

methanation reaction play an additional role, turning carbon dioxide into

carbon monoxide and methane and so lowering the hydrogen-to-carbon

monoxide ratio:

-

CO

2

+H

2

!

CO+H

2

O

ð

RX

:

7

:

3

Þ

CO+ 3H

2

!

:

:

CH

4

+H

2

O

ð

RX

7

4

Þ

Search WWH ::

Custom Search