Environmental Engineering Reference

In-Depth Information

t, the Bucyrus-Erie 4250W walking dragline at Ohio

Power Company's Muskingum mine was not far behind.

Such machines allowed the maximum overburden to coal

ratio to rise from 1-2 before WW II to 5-6.

Mining mechanization resulted in the consolidation of

coal extraction into a smaller number of larger opera-

tions, and the rising productivity of labor led to falling

labor force totals and plummeting occupational deaths

and injuries. In Germany's Ruhr region the share of me-

chanical coal extraction rose from less than 30% in the

early 1950s to more than 95% by 1975 while the total

number of operations fell by about 90% (Erasmus

1975). The average productivity of U.S. underground

mining rose from less than 1 t per work shift in 1900 to

more than 3.5 t per labor hour by 2003. In surface oper-

ations it approached 10 t per labor hour, with productiv-

ities as high as 6 t per labor hour in longwalls and 35 t

per labor hour in the surface mines in Wyoming (EIA

2006b). By the year 2000 U.S. coal mining produced al-

most four times more fuel than it had in 1900, with less

than 20% of the former labor force. At the same time, ac-

cidental deaths declined by 90% since the early 1930s

(MSHA 2000).

Extraction productivities span a broad range, from no

more than a few hundred kilograms (2-6 GJ) in primi-

tive small rural Chinese mines to more than 2,000 t per

workday (

>

40 TJ) in the largest U.S. surface mine. Dif-

ferences in seams and extraction techniques result in un-

derground power densities as high as 1-2 kW/m

2

in

longwall mining but only 100-200 W/m

2

in smaller

pits with thin seams. Surface mining needs more land

than just the area overlying the worked seam, for tempo-

rary displacement of overburden before eventual recla-

mation and for on-site transportation and buildings. The

power densities of extraction in opencast mines are com-

8.4

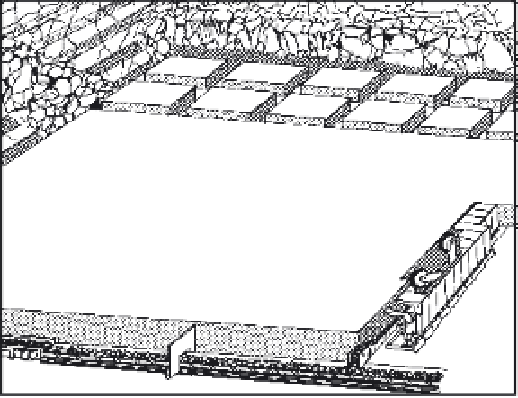

Comparison of traditional room-and-pillar extraction and

modern longwall mining. From Smil (2003).

mining health risks are additional factors responsible for

the growing adoption of surface mining. By 2000 it pro-

duced 65% of U.S. output, about 40% of Russian output,

but less than 10% of Chinese extraction.

Remarkable economies of scale were achieved by using

larger shovels and walking draglines to remove thick

overburden layers (Hollingsworth 1966). In the United

States, Bucyrus-Erie and Marion were the dominant

makers of these machines (G. B. Anderson 1980).

Capacities of the largest shovel dippers rose from 2 m

3

in 1904 to 138 m

3

in 1965. Similarly, bucket volumes

of the largest walking draglines increased from less than

3m

3

before WW I to 168 m

3

. These machines had to

be erected on site, and they consumed as much electricity

as a city of 15,000-20,000 people (the world's largest

one, as much as 100,000 people). With 12,700 t, the

Marion 6360 shovel, built in 1965 for Captain Mine in

Illinois, was the world's heaviest excavator. With 12,247