Environmental Engineering Reference

In-Depth Information

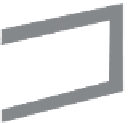

Figure 5.6

Structure of a photovoltaic module.

The connections of the solar cells are linked to a module connection box. Individual

faulty cells or uneven shade can damage a PV module. Bypass diodes that compen-

sate for affected cells when a fault occurs are designed to prevent any damage. These

diodes are also usually integrated into the module junction boxes.

5.2.3 Thin Film Solar Cells

Crystalline solar cells require a comparatively large amount of costly semiconductor

material. Different production methods using thin fi lm cells are being tested to

reduce the amount of material needed. Whereas crystalline solar cells reach thick-

nesses in the order of tenths of millimetres, thin fi lm solar cells are thousandths of

a millimetre thick. The production principle is similar even when different materials

such as amorphous silicon (a-Si), cadmium telluride (CdTe) or copper indium dis-

elenide ( CIS ) are used.

The base of thin fi lm solar cells is a substrate that is usually made of glass. Plastic

can be used instead of glass for the substrate to produce modules that are fl exible

and bendable. A thin TCO (Transparent Conductive Oxide) layer is applied to the

substrate using a spraying technique. A laser or a micromiller then separates this

layer into strips. The individual strips constitute the single cells within the later solar

module. Like crystalline cells, these cells are also contacted in such a way that

they are connected in series to increase the electric voltage. The long strips make

it visually easy to distinguish thin fi lm modules from crystalline solar modules

(Figure 5.7 ).

The semiconductor and doping materials are then vaporized at high temperatures.

When silicon is vaporized as a semiconductor material, the crystalline structure of

the silicon is lost. This is then referred to as amorphous silicon. A screen-printing

procedure then applies materials like aluminium to the back side contact. A layer

of polymer seals the cell at the back to protect it from moisture.

The effi ciency of thin fi lm modules is currently still considerably less than that of

crystalline photovoltaic modules. This means that a larger surface is required for