Environmental Engineering Reference

In-Depth Information

4.2

Electrically Enhanced Oil Recovery (EEOR) -

EK Assisted WF

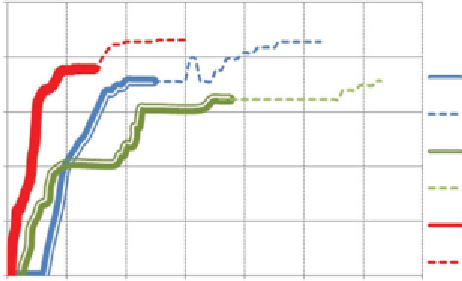

Many waterflooding operations in carbonates present serious problems

because of the plugging of pores by clays, bacteria, etc. Even greater prob-

lems occur in tight carbonate rocks, i.e., when water “does not move in”. By

applying DC current, the water moves in much better (e.g., see figure 4.1

and figure 4.2).

This increase in the oil recovery obtained from application of DC elec-

trokinetics can be explained due to the hydrodynamic flow supported by

the electrokinetic flow, which is the motion of liquid induced by an applied

potential across a porous material, capillary tube, membrane, micro chan-

nel, or any other fluid conduit. This electrokinetic phenomenon is signifi-

cantly enhanced when the flow takes place across small conduits especially

in oil-wet reservoirs where most of the oil is by-passed.

The increment in displacement efficiency of about 10-17% results in an

increase in residual water saturation of about 4-17%. This is due to the

decrease in oil saturation in the cores as the core plug turns into water-wet

from an oil-wet initially.

The average reservoir flow rate of 0.1 ml/min was used corresponding to

the average flow rate of 1 ft/Day in carbonate reservoirs. It was shown that

a lower flow rate of 0.1ml/min yielded higher oil displacement efficiency

100

80

Core - 6 - WF

60

Core - 6 - (WF + EK)

Core - 7 - WF

40

Core - 7 - (WF + EK)

20

Core - 8 - WF

Core - 8 - (WF+EK)

0

0

2

4 6

Number of injected pore volumes

8

10

12

14

Figure 4.1

Displacement Efficiency (%) versus number of injected pore volumes in

experiments conducted on a 1-in core at a flow rate of 0.1 ml/min.

Search WWH ::

Custom Search