Geology Reference

In-Depth Information

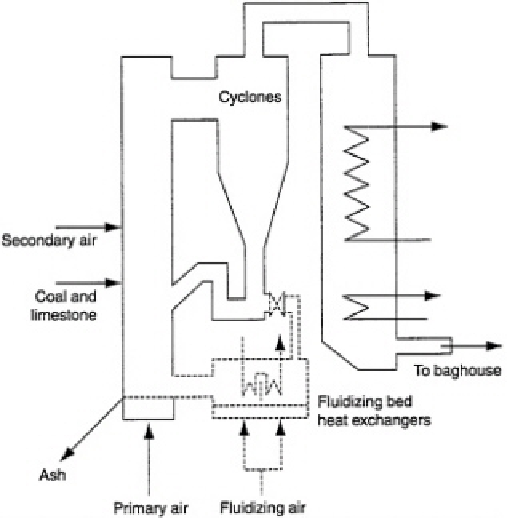

FIGURE 7.4 Typical circulating fluidized bed arrangement. Reprinted, with

permission, from Rousaki and Couch, 2000. Courtesy of IEA Coal Research.

percent fuel-to-electricity efficiency level and have near-zero NO

x

, SO

2

,

and participate emissions. Market entry is projected for 2008 (DOE, 2001).

Coal-water slurry has advantages as a feed for pressurized fluidized-bed

systems, as compared with dry lump coal, because it can be easily introduced

by pumping (J.Morrison and B.Miller, Pennsylvania State University, personal

communication, 2001).

Fluidized-bed combustion has also been demonstrated for low heat content

waste found in piles in the Pennsylvania anthracite and bituminous mining

regions and elsewhere. At least 14 such plants are operating in Pennsylvania

(Couch, 1998), and additional plants have operated in West Virginia and

Illinois. Similarly, fluidized-bed plants in Utah and Montana burn coal from

mine refuse piles consisting of low-grade surface coal layers discarded during

the beginning of surface mining operations (Couch, 1998;

Search WWH ::

Custom Search