Civil Engineering Reference

In-Depth Information

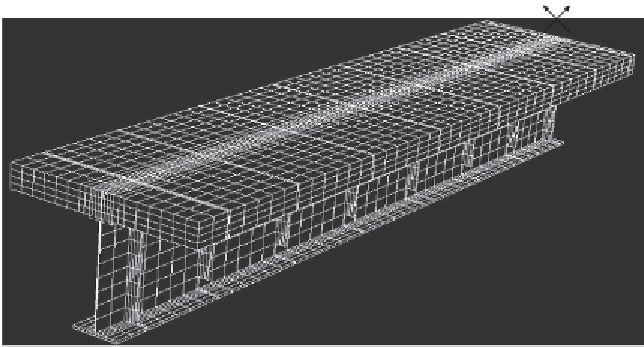

RC concrete slab

3

2

Vertical stiffener

Stud

connector

locations

1

Steel girder

Bearing location

Figure 7.2 Finite element mesh of composite beam G1.

type of concrete slab, diameter of stud, height of stud, strength of stud, and

concrete strength (see Section 5.6 of

Chapter 5

in this topic). Earlier exper-

imental and numerical investigations reported by the author [2.68,2.69] pro-

vided detailed information regarding the capacity and load-slip behavior of

headed stud shear connectors in composite girders with solid slabs. In this

dicted based on the detailed experimental and numerical investigations

[2.68,2.69]. Following the same approach [2.68,2.69], the load-slip charac-

teristic of the stud was inserted in the finite element model (

Figure 7.2

)

using

nonlinear springs in direction 2-2 at the location of the headed studs. On the

other hand, the vertical pressure between the concrete slab and the steel

beam was simulated by vertical rigid springs with high stiffness in direction

3-3 at the locations of the headed studs.

The steel plate girder-concrete slab interface was modeled by interface

elements available within the ABAQUS [1.29] element library. The method

requires defining two surfaces that are the master and slave surfaces. In

modeling the steel beam-concrete slab interface, the master surface within

the model was the top flange of the steel beam upper surface and the slave

surface was the bottom surface of the concrete slab. The interface elements

are formed between the master and slave surfaces and monitor the displace-

ment of the slave surface in relation to the master surface. When the two

surfaces remain in contact, the slave surface can displace relative to the

Search WWH ::

Custom Search