Civil Engineering Reference

In-Depth Information

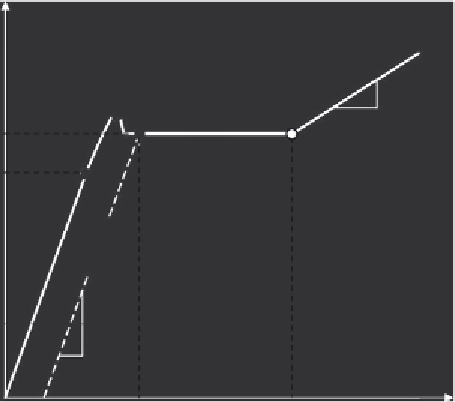

Stress

E

st

f

y

f

p

0.2 %

offset

line

E

s

e

y

e

st

Strain

Figure 2.2 Initial part of the stress-strain curve for steels with a yield plateau.

corresponding to the tensile strength

f

u

. The slope of the stress-strain curve

constantly varies during strain hardening. The tangent slope of the curve at

the onset of strain hardening (

E

st

) is often used for analysis of steel behavior at

high strain levels. Tensile coupon test results are usually presented by engi-

neering stress-strain curves where stress is calculated based on the unde-

formed cross-sectional area of the specimen. As the specimen is loaded,

the cross-sectional area is constantly being reduced, which is known as neck-

ing phenomena. The true stress at any given point can be calculated with

respect to the contracted area at that point in time. In nonlinear structural

analyses, true stress-strain curves should be used.

Figure 2.3

shows typical

f

y

70 ksi (483 MPa) show definite yield plateaus with similar ductility.

The HPS 100W steel does not have a clearly defined yield plateau and shows

slightly lower ductility compared to the lower-strength steels. The amount

of strain hardening decreases with increasing yield strength. The minimum

steel grades included in the A709 specification. Plates with thickness up to

4 in. (101.6 mm) are available in all grades, except for 50S. Rolled shapes are

not available in the HPS grades. The shear yield stress (

f

yv

) can be determined

Search WWH ::

Custom Search