Civil Engineering Reference

In-Depth Information

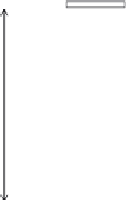

Load

Load

178×102 UB 19

Profiled sheeting

D

=75

H

= 425

A142 Mesh reinforcement

B

=450

(a)

Elevation

Figure 5.31 Arrangement of the pushout test conducted by Kim et al. [2.58, 2.59].

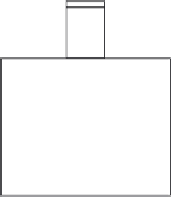

(b)

Side view

stud welded through deck in composite slabs with profiled steel sheeting.

The pushout test specimen arrangement is shown in

Figure 5.31

.Thesteel

beam used was a 178

102

19 kg/m UB section having two

13

65 mm headed studs welded on each flange of the steel beam through

the profiled steel sheeting. The profiled steel sheeting had a depth (

h

p

)of

40 mm, average width (

b

o

) of 136.5 mm, and plate thickness (

t

)of

0.68 mm. The composite concrete slab had a depth (

D

) of 75 mm, width

(

B

) of 450 mm, and height (

H

) of 425 mm. Reinforcement bar mesh of

6 mm diameter and 200 mm spacing between two bars was placed on the

top of the profiled sheeting. The concrete slabs of the pushout tests conducted

by Kim

et al.

[2.58, 2.59] had the average measured concrete cube strengths of

34.5 MPa, average tensile strength of 2.42 MPa, and Young's modulus of

21.7 GPa. The steel beam had the measured yield stress of 288 MPa and

Young's modulus of 189 GPa. The profiled steel sheeting had the measured

yield stress of 308 MPa and Young's modulus of 184 GPa. The headed shear

studs had the measured yield stress of 435 MPa. The load was applied on the

upper part of the steel beam. The movement of the composite concrete slabs

relative to the steel beamwas measured using six dial gauges attached to either

the profiled steel sheeting near the studs or the concrete top surface. The test-

ing arrangements and procedures as well as the specimen dimensions are

detailed in Kim

et al.

[2.58, 2.59]. On the other hand, pushout tests conducted

by Lloyd and Wright [2.57] provided the shear connection capacity of a

19

100 mm headed stud welded through deck in a composite slab with pro-

filed steel sheeting. The profiled steel sheeting had a depth of 50 mm, average

Search WWH ::

Custom Search