Civil Engineering Reference

In-Depth Information

The bearing is also subjected to a lateral force from the braking forces of

moving traffic as well as subjected to a longitudinal force from the reactions

of the lower wind bracings, which cause moments around longitudinal and

lateral directions of the bearing base, respectively. Similar to the roller bear-

ing, the material of construction for the bearings is cast iron steel (ISO 3755)

340-550 having a yield stress of 340 MPa and an ultimate stress of 550 MPa.

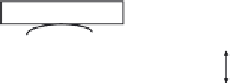

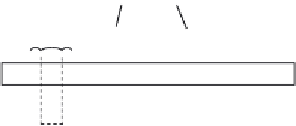

It should be noted that the overall height of the hinged bearing must be

exactly the same as that of the roller bearing. The general layout and assumed

dimensions of the hinged line rocker bearing are shown in

Figure 4.125

.

The

braking

Q

lk

forces can be calculated as follows.

the forces). Also, the reactions from the lower wind bracings (

R

tot

) (see

Figure 4.124

for the direction of the forces) were previously calculated as

follows:

9kN

We can now determine the normal stress distribution due to the applied

loads, shown in

Figure 4.124

,

on the concrete foundation as follows:

R

tot

¼

212

:

M

y

I

y

x

N

A

M

x

I

x

y

f ¼

N

A

¼

2193

36

10

3

950

1100

¼

2

:

:

098MPa

9

10

3

M

x

I

x

y ¼

212

190

950

1100

3

:

550

¼

0

:

21MPa

=

12

6

10

3

M

y

I

y

x ¼

489

190

1100

950

3

:

475

¼

0

:

56MPa

=

12

f

max

¼

2

:

098

0

:

21

0

:

56

¼

2

:

87MPa

4

4

5

13.5

10

4

5.5

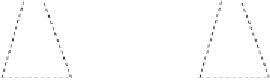

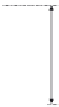

Figure 4.125 The designed roller and hinged line rocker fabricated steel bearings.

Search WWH ::

Custom Search