Civil Engineering Reference

In-Depth Information

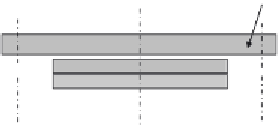

Top plate

Piston (with PTFE

bonded on top)

Sliding plate

(stainless steel)

Bottom plate

Elastomer

Figure 3.41 Pot bridge bearings.

a sliding element to accommodate translational movements in one or any

direction. This can be achieved by a PTFE (polytetrafluoroethylene)/stain-

less steel interface, usually arranged as shown in

Figure 3.41

.

The coefficient

of friction on the sliding surface depends on the PTFE interface pressure and

is typically 5%. Pot bearings may be fixed, or guided, by providing suitable

lateral restraints between the top and bottom plates. Proprietary elastomeric

bearings may be of strip, rectangular pad, or laminated type. Laminated elas-

tomeric bearings (see

Figure 3.42

)

are economic for loads up to 1000 kN

capacity. For loads greater than 1000 kN, the bearings may become uneco-

nomically large. Therefore, elastomeric bearings are rarely used for steel

highway or railway bridges. The design of elastomeric bearings is governed

by serviceability limit state requirements, to control excessive distortion of

the material. Movements and rotations are achieved by deformation of the

elastomeric material (see

Figure 3.43

). Movement is restricted to about

40 mm from the mean position.

Proprietary cylindrical bearings consist of a backing plate with a convex

cylindrical surface (rotational element) and a backing plate with a concave

Figure 3.42 Laminated elastomeric bridge bearings.

Search WWH ::

Custom Search