Environmental Engineering Reference

In-Depth Information

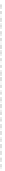

1, 2 - Storage basins

3 - Sedimentation basin

4 - Microscreen filter

5 - Mixing basin

6 - Denitrification reactor

7 - Ozonation reactor

8 - Foam condenser

9 - DO

3

stripping chambers

10- Trickling filter

11- Flocculation jar

12- Ozone generator

13- Ozone monitor

Residual gases

Foam

8

Condensed

foam

Wo r k in g

flow

9

N

2

Air

Recycled

flow

Raw influent

7

Residual gases

10

Raw

i

nflue

nt

13

CH

3

OH

3

6

4

12

11

1

2

5

Overflow

stream

Sludge

Effluent

O

2

O

2

+ O

3

Fig. 1. Schematic diagram of pilot-scale wastewater treatment train at Blue Ridge

Aquaculture. Details are not drawn to scale.

Water

flow

Gas

flow

1

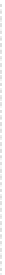

TF

used

3

O

3

conc.

O

3

dose

Oz. time Recircul. DR

2

Treatment

mg O

3

/l

water

lpm

lpm

mg O

3

/l gas

min

lpm (%)

%

1

22

36.6

6

6

4 (40%)

100

2

33

55.0

10

3

33

82.5

4

9

6 (60%)

50

4

22

55.0

1

Flow of the O

2

/O

3

mixture.

2

Recirculation rate in the denitrification reactor.

3

Proportion of cross section of trickling filter used.

Table 2. Controlled parameter conditions applied to the pilot station for the four

experimental treatments.

Search WWH ::

Custom Search