Environmental Engineering Reference

In-Depth Information

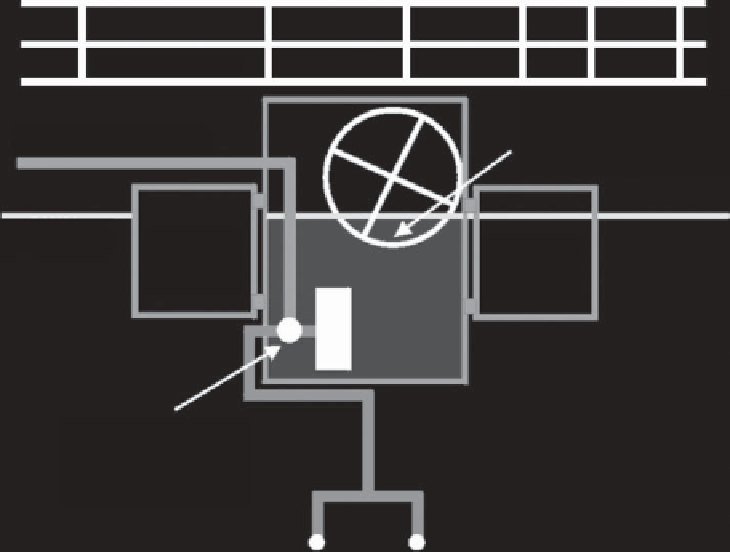

PAVEMENT LEVEL

WATER INTAKE

AT BACK OF UNIT

(CYLINDRICAL SCREEN

WITH ROTATING BRUSES

TO PREVENT BLOCK AGES)

OXYGEN SUPPLY (GAS)

PONTOONS

(FLOATING

MECHANISM)

CANAL

WATER LEVEL

PONTOONS

(FLOATING

MECHANISM)

SUPPLY

WATER

WATER

PUMP

VENTURI INJECTION

(WATER/OXYGEN

MIXING SYSTEM)

TWIN DIRECTIONAL

NOZZLE OUTLET

(OXYGEN RICH WATER)

Figure 14.7.

Schematic representation of an oxygenation unit.

(Lloyd & Whiteland

1990

). A near continuous supply (

85%) of oxygen injection

is required in the MSC during the summer, based on the frequency of DO

concentrations falling to less than 4mg L

1

at temperatures of over 16

o

Cas

measured at Trafford Road Bridge (APEM

1990b

). The extremely high SOD and

associated eruption of sediment rafts meant that a certain amount of dredging

was also necessary, as it was unlikely that oxygen enriched water would be able

to penetrate the 0.5m deep sewage-derived sediment layer.

Following the successful trial, designs for the upper MSC oxygenation system

were finalised in February 2000 (APEM

2000

). It was planned that the system

would be operated for a total of 10 years during the summer months when the

poorest water quality in the MSC occurs. Several configurations were con-

sidered but, based upon technical, planning, security and navigational issues,

the five units were located as shown in

Fig. 14.8

. The system comprises a

pipeline which distributes oxygen from a single bulk storage tank located near

Mode Wheel Locks to five oxygen injection units situated at strategic locations

in the Turning Basin (

Fig. 14.8

). Each oxygen injection unit is capable of

supplying 3 Te (tonnes) O

2

per day (125 kgO

2

hr

1

), with an overall maximum

>