Environmental Engineering Reference

In-Depth Information

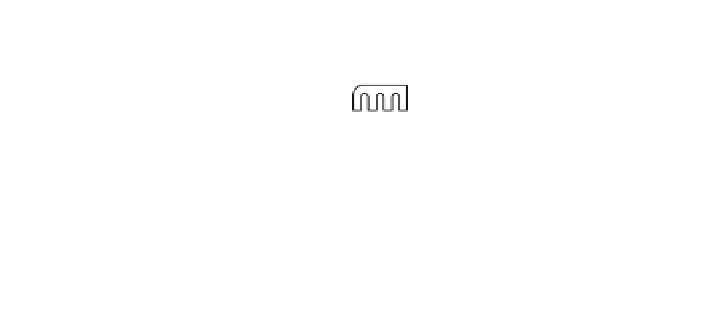

compressor

compressor belt drive

magnetic

coupling

throttle

charged air

cooler

fresh air

crank-

shaft

waste gate

exhaust

gas

air filter

flap

ventilation

turbo-fill

catalyst

Fig. 17.2

Use of a positive displacement compressor in a four-cylinder spark ignition engine

required high temperature resistance in turbines constructors use nickel-based steel

alloys [

5

].

Further devices are valves and pressure regulators for flexibly steering the

charging air and the additional use of a compressor with an electric booster pro-

viding compressed air from the air reservoir.

17.1.1.4 Compressor Technology

Turbochargers can be started only when the engine produces sufficient exhaust gas.

The turbo lag in the first seconds of start is an unfavorable side effect of this

technology. Positive displacement compressors improve the engine response

without significant delays or turbo lags. They need a direct drive, which is taken

off at the crankshaft; see Fig.

17.2

.

Positive displacement compressors usually run up to 2,000-2,400 rpm; the

turbocharger starts at higher rpm. Future compressors will need high temperature-

resistant materials, in the air intake as well, because they will operate with a higher

number of revolutions and therefore at a higher charge air temperature. Monitoring

emissions will

become

more important to achieve

improved inspection

and

maintenance under extremely raw operation conditions [

6

].

Engine performance due to fully loaded and optimized compressor technology has

increased by about 15% in the last years. However, the use of compressors also has

disadvantages, such as the higher fuel consumption and the delayed start of the

catalyst. The operation temperature of the exhaust gas after treatment system is higher

compared to the turbocharged system and an early aging of the catalyst is possible.

The combined use of a turbocharger and a compressor needs less space than

two turbochargers usually placed above the engine, because the turbocharger and

the compressor can be put between the cylinder heads. This construction has a

lower temperature in the engine compartment compared to two turbochargers.

A lower temperature with better aerodynamics partly compensates for the higher

fuel consumption.

Search WWH ::

Custom Search